Advantages of Ky Nailing equipment in woodworking industry

Introduction to Ky Nailing Equipment in the Woodworking Industry

Woodworking really depends on good nailing equipment since there are so many different kinds out there, all designed for particular jobs. Pneumatic nailers are probably what most people think of first, but don't forget about hydraulic systems for heavier work or those staple guns that handle thinner materials. These tools basically hold everything together when building furniture or cabinetry, making sure joints stay strong while also looking clean and professional. Investing in decent quality gear makes a huge difference because it speeds things up and improves the finished result. When tools perform reliably day after day, workers spend less time fixing mistakes and more time working on detailed parts of projects that require skill instead of just brute force. That kind of consistency ultimately leads to better customer satisfaction across the board.

Advantages of Using Ky Nailing Equipment for Woodworking

Utilizing Ky nailing equipment in woodworking can significantly enhance production efficiency. This equipment allows for faster nailing processes compared to manual methods, with improvements often citing up to a 50% reduction in nailing time. Such efficiency allows woodworkers to complete projects quicker and take on more jobs.

Besides being fast, Ky nailing gear really shines when it comes to getting things just right every time. The control systems these machines have actually make sure nails go where they should, which cuts down on mistakes pretty substantially. Woodworking shops report seeing around a 30% drop in those pesky nailing errors after switching to Ky equipment. That means better finished products overall and not so much wasted material lying around the shop floor.

The bottom line gets better too, which is why so many businesses are making the switch to Ky equipment. Take one manufacturing plant for example they got their money back in under twelve months after cutting down on staff hours and boosting output at the same time. What's really interesting about these systems is how they save money right away while setting companies up for bigger profits down the road. The machines handle tasks faster than traditional methods, meaning less downtime between production runs and fewer errors that waste materials. Some shops report being able to take on extra orders without hiring more workers simply because the workflow becomes so much smoother once these units are integrated into daily operations.

Key Features of Ky Nailing Equipment

Ky Nailing Equipment has some pretty cool automated systems that make their whole operation run smoother while cutting down on those expensive labor costs. When companies start using these automated nail production lines, they're looking at saving around 30 percent on what they used to spend on workers. The machines just take over all those repetitive jobs people used to do by hand. And it's not just about saving money either. With all that manual work handled by machines, employees get to focus on actually important stuff instead of wasting time on boring assembly line tasks. This shift really does boost productivity across the board for most businesses that implement it properly.

Ky's equipment can adjust its speed based on what each job actually needs, which makes it really flexible for different operations. For companies needing to produce nails at varying rates throughout their projects, this adaptability means they can change things up smoothly without any drop in product quality. The machines come with both fast production modes and precise setting options too, so manufacturers handling everything from small batches to large scale orders find them pretty handy across a wide range of production scenarios.

Ky Nailing Equipment stands out for its robust safety features that meet and often exceed industry standards for worker protection. The machines comply with important regulations from organizations like ANSI and OSHA, which means manufacturers can trust them on the shop floor. What really sets these tools apart are things like quick response emergency stops and smart systems that catch errors before they become problems. These built-in safeguards help prevent workplace accidents while keeping operations running smoothly across different manufacturing environments. Safety isn't just a box to check here it's woven into every aspect of how these nailers perform day after day.

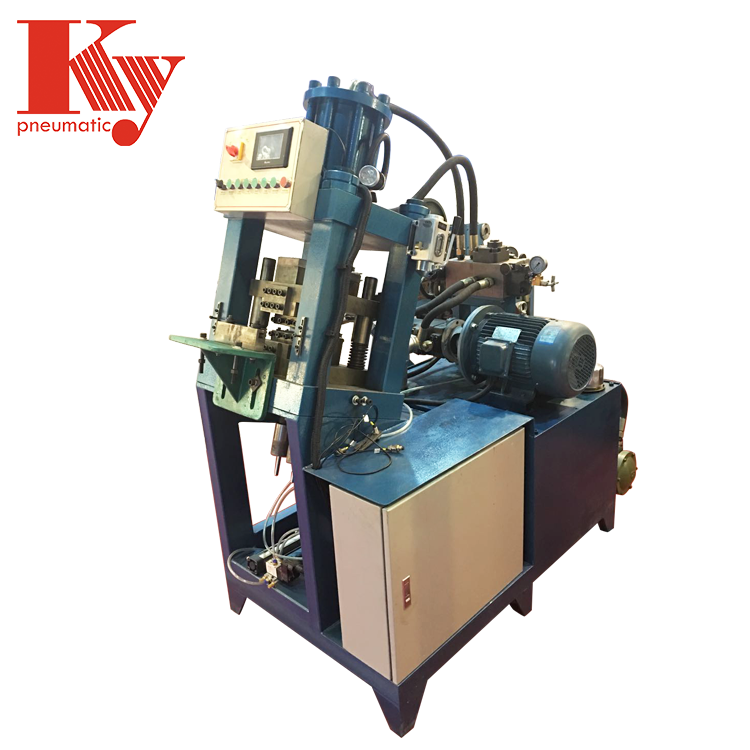

Product Spotlight: Auto Pneumatic Brad Nail Making Machine

The Auto Pneumatic Brad Nail Making Machine was created to meet all sorts of different manufacturing needs across various industries. The machine can produce anywhere from 70 to 125 nails every minute, so operators can adjust speeds depending on what their particular job requires at any given time. Inside this heavy duty equipment sits a strong 7.5KW motor running on standard industrial power (380 volts, three phase, works with both 50 and 60 hertz). This gives the machine plenty of punch when tackling big production runs. Measuring 1650 by 1000 by 1660 millimeters and weighing in at around 2800 kilograms, the unit stands solidly on factory floors, built to last through years of continuous operation without showing signs of wear.

What really sets this machine apart is how it can run two units at once with just one person watching over things. That cuts down on staffing needs while keeping output rates high, which makes a real difference for production budgets. The heart of the operation is the PLC automated control system. Operators get three options here: go hands-on with manual controls, let the machine handle most of the work in semi-auto mode, or switch everything over to full automation when needed. Another smart feature worth mentioning is the built-in auto lubrication system. It keeps those molds running smoothly without constant maintenance checks, so parts stay consistent quality wise and downtime gets minimized across shifts.

Support doesn't stop once someone buys the Auto Pneumatic Brad Nail Making Machine. We provide detailed manuals along with video guides showing how to troubleshoot common issues during operation. If customers run into problems, they can reach out through WeChat for help from our tech team. For those outside China, we can actually dispatch engineers to their facility to get everything running properly. These experts will handle both installation and fine tuning so the machine works well within existing production setups without causing disruptions or delays in manufacturing schedules.

Comparative Analysis: Ky Nailing Equipment vs. Traditional Methods

Looking at how efficient Ky Nailing Equipment really is compared to old school methods shows just how much better these new devices perform. Most traditional approaches still depend heavily on hand work which means things get done slower and take longer overall. The Ky stuff? Well it's built with all sorts of smart automation tech that just keeps cranking out results faster. Take their hydraulic models for example many users report seeing around a 30% boost in production speed. Why? Because these machines handle so many steps automatically without needing constant human oversight throughout the process.

When it comes to output quality, there's a clear difference between these approaches. Ky Nailing Equipment delivers consistently good finishes thanks to its precise engineering and those modern control systems we all know as PLCs. The end result? Fewer mistakes and products that look pretty much the same every time something traditional methods just can't match. Industry data shows that automated nailing produces better quality products most of the time. Contractors who've made the switch often mention how much easier it is to maintain standards without constant supervision.

Looking at things over the long haul, Ky equipment actually saves money compared to old school methods in the end. The numbers tell us that yes, buying Ky machines upfront costs more cash, but all those daily savings from running them start adding up pretty fast. Take a look at real world situations where companies switch over - they find themselves spending less on workers because these machines do so much work automatically. Plus, they eat up way less electricity than conventional tools. Most businesses notice their investment starts paying off after just two or three years of operation. What this means is not only are wallets feeling lighter month after month, but companies can also redirect funds towards other important areas instead of constantly patching holes in their budget.

Conclusion: The Future of Woodworking with Ky Nailing Equipment

Woodworking tech has changed quite a bit lately, as new tools are changing how things get done in shops across the country. Take Ky Nailing Equipment for instance they've really caught on with woodworkers looking to upgrade their setup. These machines work well alongside other modern gear, making jobs faster and requiring less manual labor than old school methods. Shops that have switched to Ky systems report noticeable improvements in workflow efficiency. While some purists still prefer hand tools, most professionals recognize that these advancements represent where the industry is heading. The bottom line? Better equipment means getting more done without breaking a sweat.

Putting money into Ky Nailing Equipment brings both quick fixes for day-to-day operations and bigger gains down the road for the whole industry. The tech behind these machines is changing how woodworkers do business, offering better accuracy, faster work times, and savings on materials. We're seeing a clear trend toward automated tools across workshops nationwide. Shops that upgrade their gear tend to stay ahead of competitors while handling larger projects without breaking a sweat. Many manufacturers report being able to take on bigger contracts simply because they can deliver consistent quality at scale something smaller shops just couldn't manage before this equipment became available.

FAQ

What types of nailing equipment are commonly used in woodworking?

Common types include pneumatic nailers, hydraulic machines, and staple machines, each designed for specific tasks in woodworking.

How does Ky Nailing Equipment improve efficiency?

Ky Nailing Equipment enhances efficiency by reducing nailing time by up to 50% and cutting down errors by 30%, leading to quicker project completion.

What kind of support is available after purchasing Ky Nailing Equipment?

Customers receive product instructions, machine debugging videos, and technical support via WeChat. Overseas service can also be arranged for setup assistance.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ