Backed by CE Certification, What Enables KY Nailing Equipment to Conquer 160 Countries?

CE Certification: The Global Quality Benchmark

Why CE Marking Matters in Construction Equipment

CE marking is a key certification indicating compliance with European health, safety, and environmental protection standards. For consumers and businesses alike, this ensures that products are safe, reliable, and of high quality. In the construction equipment sector, CE marking is particularly crucial, as it enhances trust and safety by demonstrating that the equipment has been evaluated to meet the mandates of applicable EU directives. This kind of verification is essential in environments where machinery safety is of utmost importance.

Moreover, CE marking significantly boosts the marketability of products within the European Union. As a competitive arena for construction equipment manufacturers, having a CE mark allows companies to operate effectively within the EU's single market. This certification not only opens up new business opportunities but also provides a competitive advantage by showcasing adherence to stringent safety and quality standards. Products with CE marking are more likely to be viewed favorably by both businesses and end-users, contributing to increased sales and market presence.

Meeting International Safety & Performance Standards

For manufacturers, adhering to international safety and performance standards is non-negotiable to ensure user safety and product reliability. Such compliance with established standards, like ISO and EN certifications, is crucial for reducing instances of product recalls and potential legal issues, which can be costly both financially and reputation-wise. These certifications demonstrate a company's commitment to producing high-quality, reliable, and safe equipment.

By consistently meeting these rigorous performance standards, companies protect their reputation and enhance their brand value and customer loyalty. In a highly competitive market, maintaining customer trust is vital, and adherence to international standards is a tangible way to demonstrate this dedication. The alignment with international safety benchmarks not only safeguards the end-users but also ensures that businesses remain at the forefront of industry leadership and innovation.

Engineering Excellence Behind KY's Worldwide Appeal

PLC Automation for Precision Staple Production

Programmable Logic Controllers (PLCs) optimize the staple production process, showcasing precise control over manufacturing operations. Through these advanced technologies, KY ensures that the production is consistent and efficient, drastically enhancing the quality of staples produced. By automating the process, PLCs reduce human error and increase operational efficiency. This not only minimizes downtime but also ensures that the production is scalable to meet global demand. Such automation is vital in maintaining consistency and quality across large volumes required in the global market for staples. As KY incorporates PLC automation in its processes, it exemplifies their commitment to delivering precision and efficiency in staple production.

Dual-Operation Capabilities in Automatic Staple Machines

KY's automatic staple machines boast unique dual-operation capabilities, providing the flexibility to handle various staple specifications and thicknesses. This adaptability allows manufacturers to rapidly respond to changing market demands and specific customer requirements without the need for extensive machine adjustments. The dual-operation capability aids in enhancing production efficiency by enabling concurrent operations, which significantly reduces downtime and increases throughput. Consequently, these machines contribute to lowering production costs while boosting productivity, making KY's automatic staple machines a preferred choice for manufacturers seeking adaptability and efficiency.

Error Margin Control: 0.1mm Precision Engineering

In staple manufacturing, precision engineering is crucial, especially when an error margin of just 0.1 mm can drastically affect product performance. KY's equipment incorporates advanced measurement systems to ensure stringent quality control, meeting high standards consistently. Precision in manufacturing guarantees product reliability, enhancing customer satisfaction and confidence. By minimizing error margins, KY not only boosts product reliability but also sets a benchmark for quality in the industry. The meticulous design and engineering of their equipment reflect KY's commitment to excellence and reinforce their reputation as leaders in staple manufacturing technology.

Strategic Global Expansion Tactics

Localized Distribution Network Optimization

Optimizing the distribution network is crucial for KY to effectively respond to regional demands. This process involves strategically positioning regional warehouses to improve inventory management and ensuring that products are readily available across different markets. By reducing lead times and logistics costs, KY can dynamically adapt to market trends and enhance customer satisfaction. Utilizing regional warehouses allows for more efficient handling of inventory, thereby minimizing stockouts and ensuring quick order fulfillment.

Multi-Language Technical Support Systems

Providing multi-language technical support is essential for global customer satisfaction. Ensuring that users can access assistance in their native language fosters better communication between KY and its international clients, leading to a smoother user experience. Proficient multilingual staff at KY's support centers minimize misunderstandings and enhance the reputation of KY's after-sales services, offering a sense of reliability and trust to customers worldwide.

Onsite Engineer Deployment for Machine Commissioning

Onsite engineer deployment for machine commissioning ensures that KY's machinery is installed correctly and operational from day one. This strategic approach builds trust with customers, as they receive hands-on support and expertise during critical installation phases. Onsite support helps in reducing operational failures, contributing significantly to the long-term performance and reliability of the installed machinery. This practice ensures that KY's equipment operates efficiently, offering customers peace of mind and reinforcing KY's commitment to excellence.

KY's Flagship Nailing Machines Conquering Markets

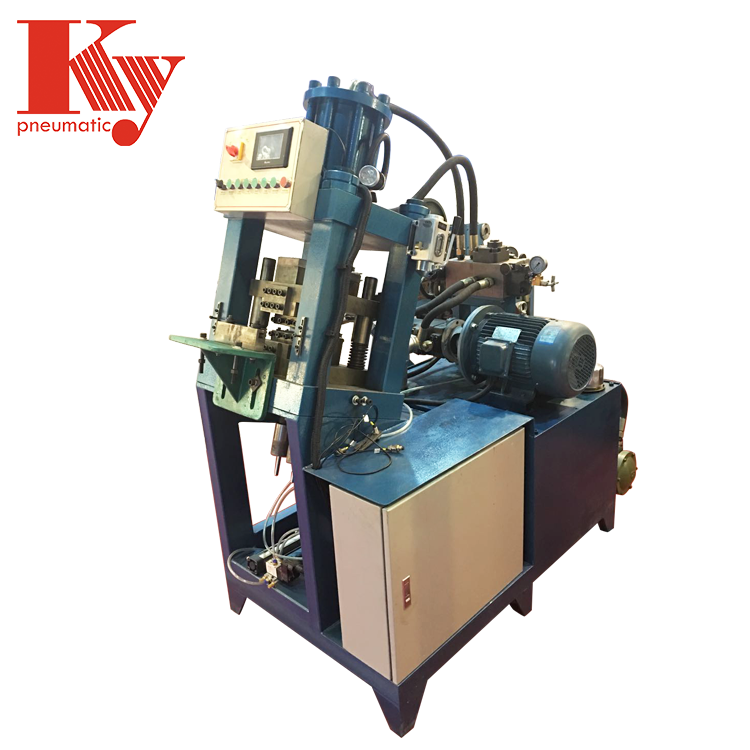

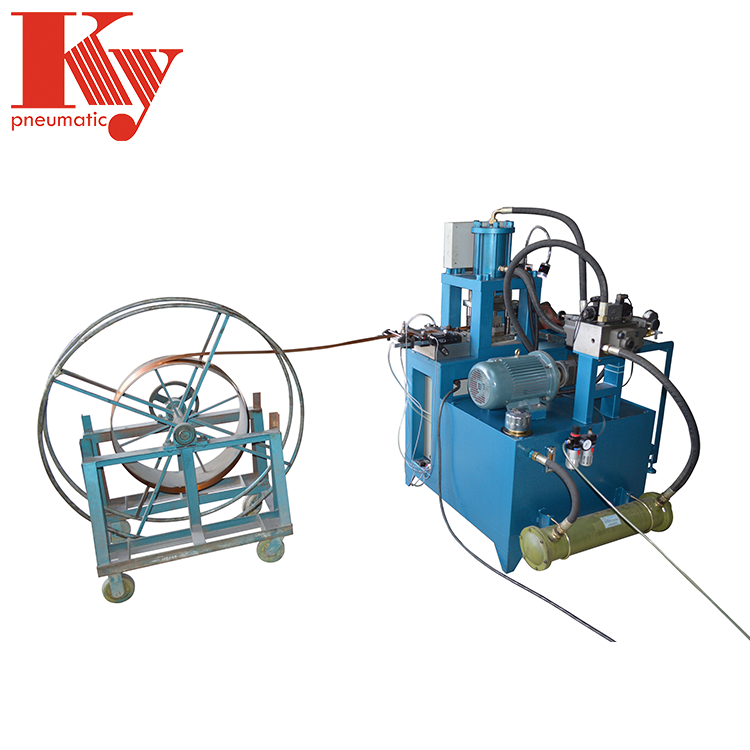

T Brad Nail Making Machine: High-Speed Band Processing

The T Brad Nail Making Machine represents a significant leap in high-speed band processing technology, designed to enhance production efficiency substantially. This machine is tailored for high-volume operations, ensuring that users meet the escalating demands across various industries, including furniture and construction. Its construction is robust, guaranteeing durability and operational reliability for large-scale manufacturing processes. By operating at high speeds, users can achieve remarkable reductions in labor costs, thereby improving the return on investment. Consequently, this machine not only boosts productivity but also ensures quality and precision in every nail produced, making it an essential asset for modern manufacturing.

F Brad Nail Machine: Compact Pneumatic Efficiency

The F Brad Nail Machine delivers precision with its compact and efficient design, perfect for facilities where space and versatility are crucial. This machine stands out with its pneumatic system, allowing decreased energy consumption and promoting sustainable production methods. Its compact form does not compromise on efficiency, offering reliable performance that meets the critical demands of diverse manufacturing environments. As industries increasingly seek systems that balance space usage and operational productivity, the F Brad Nail Machine offers an ideal solution by delivering excellent results without requiring extensive space. Thus, it supports sustainable practices while appealing to manufacturers across multiple sectors.

Auto Pneumatic System: Dual-Gauge Versatility

The Auto Pneumatic System excels with its dual-gauge versatility, allowing manufacturers to seamlessly switch between various nail sizes, thereby increasing product adaptability. This capability is particularly advantageous for industries that need a diverse range of fasteners for different applications, such as construction and furniture making. The flexibility offered by this machine supports KY’s commitment to customer efficiency and adaptability, ensuring manufacturers can meet various production demands swiftly and affordably. This system not only enhances the versatility of production but also boosts overall efficiency, providing a significant competitive edge in fast-paced manufacturing environments.

T/F Series Multi-Purpose Industrial Nail Producer

The T/F Series Multi-Purpose Industrial Nail Producer is celebrated for its combination of efficiency and versatility, making it a standout choice for various manufacturing environments. This machine is designed to handle a range of nail types while maintaining impressive throughput, a feature highly valued by manufacturers seeking to maximize production capabilities without incurring substantial additional costs. By investing in such versatile machinery, companies can maintain a competitive edge, enhance their production lines, and ultimately drive economic gains through unified and efficient manufacturing processes. The T/F Series promises flexibility and productivity, essential for tackling the challenges of modern-day production.

Sustaining International Dominance Through Innovation

IoT Integration in Wire Drawing Machine Operations

Integrating IoT in wire drawing machine operations is a transformative step towards enhancing real-time monitoring and analytics, which significantly boosts production efficiency. By embedding IoT devices, manufacturers can collect crucial data that enables them to identify bottlenecks and predict maintenance needs before they result in costly downtime. This foresight not only enhances operational efficiency but also underscores KY's ability to optimize processes, ensuring they maintain a competitive edge in the dynamic global market. With IoT, KY's wire drawing machines become smarter, allowing for continuous improvement and adaptation to market demands.

Eco-Conscious Manufacturing for EU Market Compliance

Adhering to eco-conscious manufacturing practices is of paramount importance for compliance with EU regulations and meeting consumer expectations. Implementing sustainable practices not only minimizes environmental impact but also helps attract clientele that prioritizes corporate responsibility. Investment in green technologies, such as energy-efficient systems and recyclable materials, can lead to enhanced brand loyalty and open new market opportunities across environmentally conscious regions. By aligning with these practices, KY demonstrates commitment to sustainability and positions itself favorably in regions with stringent environmental regulations, paving the way for future growth and innovation in eco-conscious manufacturing.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ