Global market trend of Ky Nailing equipment

Introduction to Ky Nailing Equipment

The global Ky Nailing Equipment market is experiencing substantial growth, with industry reports indicating a rising demand driven by its essential role in modern manufacturing. According to market research, the size of this market is projected to grow at a CAGR of approximately 5% over the next several years. This growth can be attributed to the increased automation and efficiency offered by these machines, which play a critical role in enhancing manufacturing processes.

Ky Nailing Equipment significantly contributes to modern manufacturing by providing improved efficiency and productivity gains. These machines are designed to perform intricate tasks with precision, reducing manual effort and minimizing human error. By integrating advanced technologies like PLC control systems, Ky Nailing Equipment enhances operational speed and ensures greater reliability, making it an indispensable tool in various industries.

Key Features of Ky Nailing Equipment

Ky Nailing Equipment is renowned for its incorporation of advanced technology and automation features that significantly enhance precision in manufacturing processes. Modern equipment employs sophisticated PLC control systems, which replace traditional relay controls, allowing for faster and more reliable performance. These systems ensure high precision in automation, significantly reducing human error and enhancing product consistency. For instance, the ability to perform exact and repeatable tasks ensures that manufacturing defects are minimized, which in turn results in cost savings and improved product quality.

Moreover, the production efficiency of Ky Nailing Equipment is notable, particularly when compared to traditional manufacturing methods. With the automation capabilities and technology integrated into Ky equipment, production rates have surged, exceeding industry benchmarks. Traditional methods often suffer from lower efficiency due to manual intervention and slower processing times. In contrast, Ky Nailing Equipment streamlines production processes, leading to increased output and reduced cycle times. This efficiency not only improves productivity but also shortens lead times, offering a competitive edge in fulfilling market demands swiftly.

Exploring the Uses of Ky Nailing Equipment

Ky Nailing Equipment serves a crucial role across diverse industries such as furniture manufacturing, construction, and packaging. In furniture production, the equipment is used for assembling frames and securing upholstery, ensuring durability and aesthetic appeal. Within the construction sector, it is indispensable for tasks like roofing and framing, promoting faster assembly times while maintaining structural integrity. In packaging, Ky Nailing Equipment aids in sealing boxes and crates, ensuring secure transport of goods. Each of these applications highlights the equipment's versatility and indispensability in industrial processes.

Utilizing Ky Nailing Equipment in production processes offers significant advantages. Firstly, it reduces labor costs by minimizing the need for manual effort, thanks to its automated features. Secondly, the equipment enhances product quality through precise and consistent nailing, which reduces the risk of defects. Additionally, the speed of operations is greatly increased, enabling businesses to meet high demand efficiently. By integrating Ky Nailing Equipment into their operations, companies can achieve substantial improvements in cost efficiency, product quality, and production speed, thereby enhancing overall productivity.

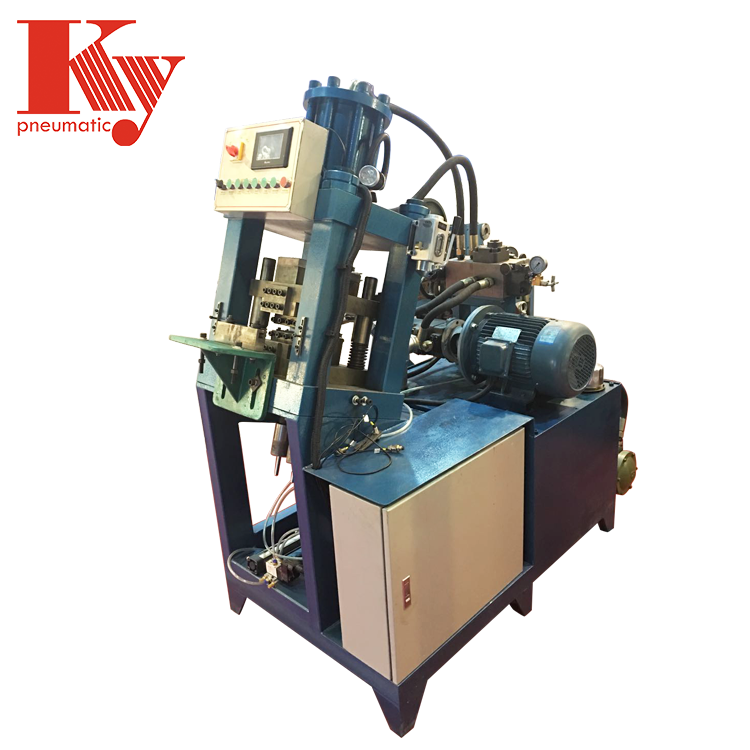

Product Spotlight: Auto Pneumatic Brad Nail Making Machine

The Auto Pneumatic Brad Nail Making Machine stands out with its sophisticated design and operational prowess. This machine is renowned for its efficient dual-operation capability, allowing a single operator to manage up to two units simultaneously, which significantly enhances production efficiency and reduces labor costs. It comes equipped with advanced PLC automated control systems that support manual, semi-automatic, or fully automatic modes, providing complete control and flexibility over the production process. Its precision in length adjustment, with an error margin of only 0.1mm, ensures consistent nail lengths and precise dimensions for every batch.

What sets this machine apart from others in the market is its incredible efficiency and cost-effectiveness. It can produce between 70 to 125 nails per minute while maintaining the quality standards required by various industries. Furthermore, the machine's intelligent automatic lubrication system and multi-layer safety protection features, such as current overload protection, promote durability and ensure operator safety. These advanced technologies not only minimize downtime but also extend the machine's lifespan, making it a superior choice for manufacturers.

Future Trends in Ky Nailing Equipment

Emerging innovations in Ky Nailing Equipment are shaping the future of the industry, with smart technology and customization options leading the way. Industry experts suggest that the integration of smart technology, such as IoT-enabled devices, is revolutionizing machine operations, making them more efficient and user-friendly. For instance, machines equipped with sensors can now monitor performance and predict maintenance needs, reducing downtime and increasing productivity. Customization options are also becoming prevalent, allowing businesses to tailor machines to meet specific production requirements, thereby optimizing efficiency and output.

Sustainability and environmental considerations are also increasingly influencing the manufacturing industry, including the production of Ky Nailing Equipment. As regulations become stricter and consumer demand for eco-friendly products rises, manufacturers are seeking ways to reduce their carbon footprint. This includes adopting more sustainable materials and processes, such as using recyclable components and energy-efficient technologies. Additionally, some manufacturers are investing in closed-loop systems to minimize waste and improve resource efficiency. These trends not only help in compliance with environmental regulations but also enhance brand reputation by aligning with global sustainability goals.

Conclusion: The Growth Potential of Ky Nailing Equipment

Innovation is the driving force behind the growth of the Ky Nailing Equipment sector. Recapping the highlighted market trends, we see that adopting smart technology and enhancing product customization are vital for staying competitive. Businesses must leverage these advancements to optimize their operations and increase productivity.

Adapting to industry changes is crucial for businesses aiming to capitalize on the potential of Ky Nailing Equipment. Market analysts emphasize the importance of staying current with evolving technologies and regulations. By aligning with these trends, companies not only ensure compliance but also place themselves at the forefront of industry innovation, poised for significant growth.

FAQ

What is Ky Nailing Equipment?

Ky Nailing Equipment is advanced machinery used in manufacturing to improve efficiency and precision, reducing manual effort and minimizing errors.

In which industries is Ky Nailing Equipment commonly used?

It is commonly used in furniture manufacturing, construction, and packaging industries for tasks like assembling frames, roofing, and sealing boxes.

What are the key features of Ky Nailing Equipment?

Key features include advanced PLC control systems, precision in automation, increased production efficiency, and reduced cycle times.

What is the Auto Pneumatic Brad Nail Making Machine known for?

This machine is known for its dual-operation capability, advanced PLC control systems, and ability to produce 70-125 nails per minute efficiently.

What are the future trends in Ky Nailing Equipment?

Future trends include the integration of smart technology like IoT, increased customization options, and a focus on sustainability and eco-friendly manufacturing processes.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ