Maintenance and care of staplers: extend the service life of equipment

Understanding Your Stapler's Components

A typical stapler comprises several essential components, each playing a crucial role in its functionality. Understanding these parts can enhance your ability to troubleshoot and maintain your stapler. The main parts of a stapler include:

Base: This provides stability and support for the stapler. In manufacturing standards, the base is designed to resist impact and distribute pressure evenly during use.

Handle: Operating as a lever, it is designed to transmit the force exerted by the user to drive the staple through the paper.

Die or Staple Channel: A metal piece that shapes and positions the staple for insertion. According to educational resources on stapler mechanics, this component ensures the proper alignment of the staple.

Anvil: Positioned at the base, it clinches (or bends) the staple ends after driving them through the material, a critical function for securing papers tightly.

Staple Magazine: This is where staples are loaded. A well-functioning staple magazine ensures a smooth and consistent staple feeding process.

Each component contributes to the overall performance of the stapler. The handle, when pressed, triggers a series of mechanical actions that involve the coordinated movement of the die and anvil. When executed precisely, this synergy ensures the stapler consistently provides reliable results. Understanding the mechanics behind these parts, such as how the staple magazine works with the die to minimize jamming risks, empowers users to maintain their devices effectively. Regular cleaning and proper loading of staples can prevent common issues, highlighting the importance of comprehending these foundational components.

General Maintenance Practices for Staplers

To maintain a stapler's longevity and efficiency, routine cleaning is crucial. Begin by safely removing debris and dust using a small brush or an old toothbrush to loosen particles hiding inside the stapler. Then, using a can of compressed air can effectively blow out finer dust from hard-to-reach areas. Make sure to wipe the exterior with a slightly damp cloth to prevent grime buildup. It’s essential to avoid excessive moisture to prevent rusting and damage to your stapler.

Proper staple loading is another critical maintenance practice. Incorrect loading can lead to operational problems like frequent jams and misalignment. First, consult your stapler's manual to determine the appropriate staple type and size for your specific model — this ensures optimal performance and prevents misfires. It's also advisable to avoid overloading the stapler. Inserting too many staples can increase pressure and result in misfires or damage to the stapler's components.

Finally, regular inspection of the staple magazine is essential. Look for any obstructions that might prevent staples from feeding correctly. Routine checks along with these maintenance practices, informed by expert guidance, will help maintain the reliability and efficiency of your stapling machine.

How to Maintain Staplers for Longevity

Maintaining staplers effectively ensures their longevity and smooth operation. For long-term non-usage care, it is essential to store staplers in a dry environment to prevent rust or moisture damage. Ensure that staples are removed before storage to avoid tension on the spring mechanism that can weaken over time.

In terms of short-term usage maintenance, regular checks for wear and tear are vital. Inspect the moving parts periodically and apply a light lubrication to hinges and spring mechanisms using machine oil. This minimizes friction and keeps components moving smoothly. However, experts advise against over-oiling, as excessive lubrication can attract dust and lead to clogging. Taking these precautions will significantly extend your stapler's life and maintain its performance efficiency over time.

Common Issues and Solutions for Stapler Maintenance

Staplers are essential tools in everyday office settings, but they often encounter common issues like jamming. Jamming occurs when staples are misaligned, bent, or when foreign objects clog the mechanism. To resolve jams, start by opening the stapler and checking for any visible obstructions. Using needle-nose pliers, carefully extract any stuck staples without damaging the components. Additionally, ensure that you're using the correct staple size for your stapler model, as mismatched staples are a frequent cause of jamming. Regularly cleaning the stapler to remove debris can prevent these issues from occurring repeatedly, thus maintaining your workflow effectively.

Another frequently encountered problem is dispensing multiple staples at once. This issue usually stems from misaligned staples, worn-out components, or even overloading the staple magazine. To remedy this, first, check the alignment of the staples and ensure they're properly positioned in the magazine. Inspect parts like springs for any signs of wear and replace them as needed. Moreover, avoid loading the magazine beyond its capacity to prevent undue pressure on the mechanism, which can lead to dispensing issues. By following these troubleshooting steps, you can eliminate the inconvenience of multi-staple dispersal, ensuring your stapler operates smoothly.

Misfiring or dispensing issues also plague staple operations, often when the hammer mechanism is clogged with debris or the staple length is incompatible with the material. Start by examining the hammer area for any blockages and clean it with a small brush or compressed air. If cleaning does not resolve misfires, consider using staples that match the specifications of your stapler. Efficient maintenance and correct staple selection can mitigate these problems, ensuring that your stapler remains in optimal working condition.

Product Recommendations for Stapler Maintenance

For effective stapler maintenance and enhanced performance longevity, several high-quality machines are available that cater to various stapler types and applications:

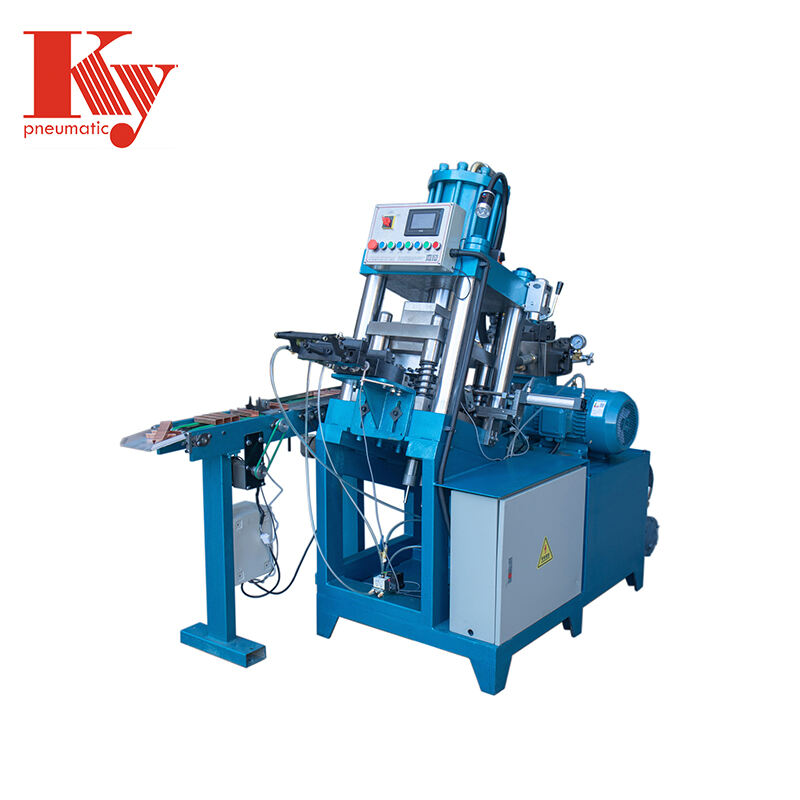

32/35/34 Carton Closing Staple Making Machine

This machine excels in pressing and forming wire bands into final product staples with hydrodynamic operations, offering stable performance and low noise output. Its ability to adjust the length of nails enhances its flexibility for diverse applications.

Mattress Clip Staple Making Machine

Incorporating advanced international manufacturing techniques, this machine minimizes energy consumption while maximizing stability and speed, essential for efficient stapler production and maintenance.

These machines significantly contribute to maintaining and improving stapler performance, thereby boosting overall productivity. Their features ensure efficient operations tailored to specific industrial needs.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ