Συντήρηση και φροντίδα του εξοπλισμού Ky Nailing

Κατανοώντας τον εξοπλισμό καρφιάς Ky

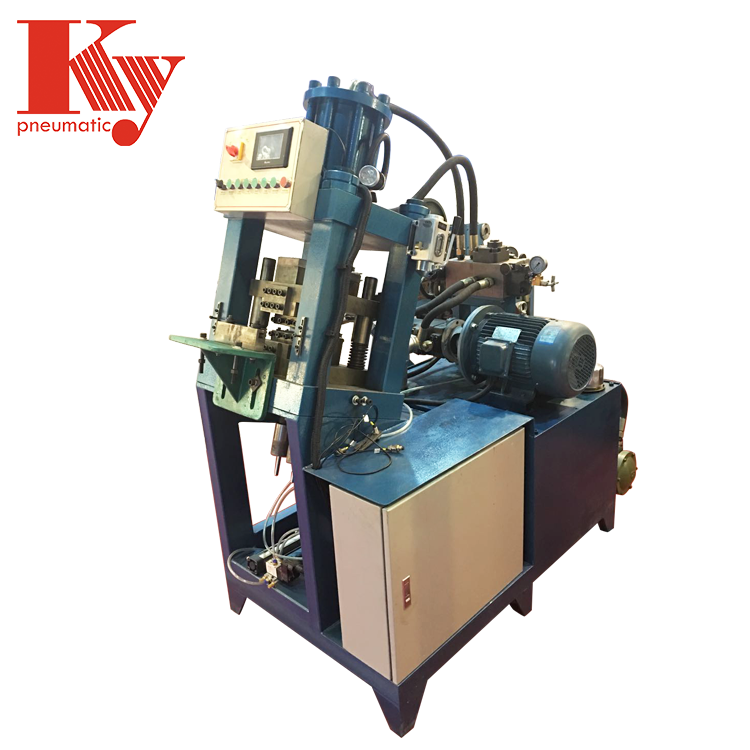

Ο εξοπλισμός Nailing Ky περιλαμβάνει εξειδικευμένα εργαλεία που είναι καθοριστικά στη κατασκευή και τη ξυλοτεχνία για τη διαδικασία καρφώματος. Αυτά τα εργαλεία, τα οποία έχουν αναπτυχθεί για ακρίβεια και αποτελεσματικότητα, χρησιμοποιούνται σε διάφορες εργασίες για να διασφαλίσουν ότι τα καρφιά θα σφυρηλατούν με ακρίβεια και ασφάλεια σε διάφορα υλικά. Από τις μηχανές συρρίκνωσης μέχρι τα υδραυλικά εργαλεία κατασκευής καρφιών, η Ky Nailing Equipment καλύπτει ένα ευρύ φάσμα συσκευών προσαρμοσμένων για να καλύπτουν τις διαφορετικές ανάγκες καρφώματος τόσο σε μικρής κλίμακας όσο και σε βιομηχανικές εφαρμογές.

Τα εργαλεία αυτά έχουν σχεδιαστεί για να αυξήσουν την παραγωγικότητα, επιτρέποντας την αποτελεσματική και ακριβή καρφώση, η οποία είναι ζωτικής σημασίας σε ταχύτατα εργασιακά περιβάλλοντα. Με την αυτοματοποίηση και τον εξορθολογισμό της διαδικασίας καρφώσεως, μειώνουν σημαντικά την εργασία και αυξάνουν την ταχύτητα παραγωγής. Τα χρησιμοποιούμενα μηχανήματα περιλαμβάνουν συχνά προηγμένα χαρακτηριστικά όπως συστήματα ελέγχου PLC, τα οποία παρέχουν ταχύτερη και πιο αξιόπιστη απόδοση από τις παραδοσιακές χειροκίνητες μεθόδους.

Η κατανόηση του εξοπλισμού Ky Nailing είναι επιτακτική για τους χειριστές και τους διαχειριστές κατασκευής. Η γνώση της διαχείρισης και της λειτουργίας αυτής της τεχνολογίας εξασφαλίζει την αποτελεσματική και ασφαλή χρήση των μηχανών. Αυτή η κατανόηση βοηθά επίσης στην αντιμετώπιση προβλημάτων και στη συντήρηση εξοπλισμού, πράγμα που είναι ζωτικής σημασίας για την παράταση της διάρκειας ζωής του και τη διατήρηση της ποιότητας της παραγωγής. Η διερεύνηση των λειτουργικών αποχρώσεων και των αναγκών συντήρησης των εξοπλισμών Nailing Ky μπορεί να οδηγήσει σε καλύτερη απόδοση και αποτελεσματικότητα στο εργοτάξιο.

Σημασία της συντήρησης για τον εξοπλισμό καρφώσεως Ky

Η τακτική συντήρηση του εξοπλισμού Nailing Ky είναι απαραίτητη για να εξασφαλιστεί τόσο η μακροζωία του όσο και η αποτελεσματική του απόδοση. Αυτά τα εξειδικευμένα εργαλεία είναι ζωτικής σημασίας για πολλές εργασίες κατασκευής και ξυλοκομίας, και αν δεν συντηρούνται κατάλληλα, μπορούν να φθαρθούν γρήγορα. Με τον συνεχή έλεγχο και συντήρηση του εξοπλισμού, οι χειριστές μπορούν να αποτρέψουν την φθορά, διατηρώντας την βέλτιστη απόδοση. Οι μελέτες δείχνουν ότι η τακτική συντήρηση μπορεί να παρατείνει τη διάρκεια ζωής τέτοιων εξοπλισμούς κατά 50%, γεγονός που τονίζει τη σημασία τους.

Η παραμέληση της συντήρησης μπορεί να έχει σοβαρές συνέπειες, όπως βλάβες εξοπλισμού που μπορεί να προκαλέσουν καθυστερήσεις στο έργο και να αυξήσουν το κόστος επισκευής. Ένα δυσλειτουργικό καρφωτήρι μπορεί να σταματήσει τις εργασίες, επηρεάζοντας την παραγωγικότητα και τα χρονοδιαγράμματα του έργου. Επιπλέον, τα έξοδα επισκευής μπορούν να συσσωρεύονται γρήγορα, εκτρέποντας τα κεφάλαια από άλλα ουσιώδη στοιχεία του έργου. Έτσι, η προτεραιότητα των πρακτικών συντήρησης μπορεί να αποτρέψει αυτές τις παγίδες, εξασφαλίζοντας ομαλή και οικονομικά αποδοτική λειτουργία. Η διασφάλιση της τακτικής λιπαντικής, καθαρισμού και επιθεώρησης του εξοπλισμού ευθυγραμμίζεται με τις βέλτιστες πρακτικές και συμβάλλει στη διατήρηση της ακεραιότητας και της αξιοπιστίας του εξοπλισμού Nailing Ky.

Ελέγχος ρουτίνας συντήρησης για τον εξοπλισμό καρφώματος Ky

Η τακτική συντήρηση είναι ζωτικής σημασίας για τη μακροζωία και την απόδοση των εξοπλισμού Ky Nailing. Η καθημερινή συντήρηση είναι το πρώτο βήμα για να διασφαλιστεί ότι ο εξοπλισμός σας λειτουργεί ομαλά. Ξεκινήστε καθαρίζοντας το εξοπλισμό μετά από κάθε χρήση για να αφαιρέσετε τυχόν υπολείμματα που θα μπορούσαν να εμποδίσουν τη λειτουργία του. Είναι επίσης σημαντικό να ελέγχετε για τυχόν σημάδια φθοράς ή ζημιάς, καθώς αν εντοπίσετε αυτά τα προβλήματα νωρίς, μπορείτε να αποτρέψετε μεγαλύτερα προβλήματα στο μέλλον. Τέλος, λιρώστε τακτικά όλα τα κινούμενα μέρη για να ελαχιστοποιήσετε τη τριβή και την φθορά.

Σε εβδομαδιαία βάση, πρέπει να ασκούνται ορισμένες εργασίες συντήρησης για να διατηρείται ο εξοπλισμός σε βέλτιστη κατάσταση. Ελέγξτε τα φίλτρα αέρα για να βεβαιωθείτε ότι είναι καθαρά και χωρίς εμπόδια, καθώς αυτά είναι απαραίτητα για τον σωστό εξαερισμό και την αποτελεσματικότητα. Ελέγξτε την ακρίβεια των καρφών με τη διενέργεια μερικών δοκιμών δοκιμής και σφίξτε τυχόν χαλαρές βίδες ή μπουλόνια για να διατηρηθεί η σταθερότητα και η ακρίβεια του εξοπλισμού.

Η μηνιαία συντήρηση θα πρέπει να περιλαμβάνει λεπτομερέστερη εξέταση ολόκληρου του συστήματος εξοπλισμού. Κάντε μια λεπτομερή επιθεώρηση για να εντοπίσετε τυχόν μέρη που πλησιάζουν στο τέλος της διάρκειας ζωής τους. Συνιστάται η επανακατατάσταση του εξοπλισμού για να εξασφαλιστεί η ακριβής και αποτελεσματική λειτουργία του. Η αντικατάσταση φθαρμένων εξαρτημάτων μπορεί να αποτρέψει απρόσμενες βλάβες, εξασφαλίζοντας έτσι την αποτελεσματική λειτουργία του εξοπλισμού και την επίτευξη των στόχων παραγωγής. Η τήρηση αυτής της ρουτίνας συντήρησης μπορεί να παρατείνει τη διάρκεια ζωής του εξοπλισμού σας και να βελτιώσει τη συνολική του απόδοση.

Επεξεργασία προβλημάτων σε συνηθισμένα θέματα στην συσκευή καρφιάς Ky

Κατά τη χρήση του εξοπλισμού Ky Nailing, οι χειριστές μπορεί να αντιμετωπίσουν κοινά προβλήματα όπως μπλοκάρισμα, ασυνεπή βάθος νυχιών και διαρροές αέρα. Τα προβλήματα αυτά μπορούν να διακόψουν τη ροή εργασίας και να μειώσουν την αποτελεσματικότητα εάν δεν αντιμετωπιστούν αμέσως. Η τακτική παρακολούθηση μπορεί να ελαχιστοποιήσει αυτά τα περιστατικά και να εξασφαλίσει την ομαλή λειτουργία.

Για να επιλύσετε αποτελεσματικά αυτά τα προβλήματα, εξετάστε τις ακόλουθες λύσεις. Για την ακαμψία, βεβαιωθείτε ότι η τροφοδοσία με τα νυχιά είναι αδιαπέραστη και καθαρίστε τυχόν μπλοκάρισμα μέσα στον εξοπλισμό. Αν παρατηρήσετε ασυνεπή βάθος νυχιών, ρυθμίστε τη πίεση του αέρα κατάλληλα για να επιτευχθεί το επιθυμητό αποτέλεσμα. Για διαρροές αέρα, ελέγξτε τις σωλήνες και τις σφραγίδες για ζημιές και αντικαταστήστε τις εφόσον είναι απαραίτητο για τη διατήρηση βέλτιστων επιπέδων πίεσης και απόδοσης.

Σε περιπτώσεις που τα προβλήματα παραμένουν παρά τις προσπάθειες επίλυσης προβλημάτων, είναι συνετό να ζητήσετε επαγγελματική βοήθεια. Αν οι δυσκολίες παραμείνουν, μπορεί να υποδεικνύουν υποκείμενα προβλήματα τα οποία, αν αγνοηθούν, μπορεί να προκαλέσουν σοβαρή βλάβη στον εξοπλισμό. Ένας επαγγελματίας μπορεί να εντοπίσει την αιτία και να σας δώσει μια ολοκληρωμένη λύση, εξασφαλίζοντας ότι ο εξοπλισμός σας θα επιστρέψει στην πλήρη λειτουργική του ικανότητα.

Προϊόντα για τη βέλτιστη απόδοση του εξοπλισμού καρφώματος Ky

Ένα βασικό προϊόν για την ενίσχυση της αποτελεσματικότητας του εξοπλισμού Nailing Ky είναι η αυτόματη πνευματική μηχανή παρασκευής νυχιών Brad. Αυτά τα προηγμένα μηχανήματα προσφέρουν πολλά οφέλη, μεταξύ των οποίων ευέλικτη λειτουργία και μειωμένη χειρωνακτική εργασία, οι οποίες είναι ζωτικής σημασίας για την αύξηση της παραγωγικότητας. Με τη δυνατότητα διπλής λειτουργίας και τα αυτοματοποιημένα χειριστήρια, η μηχανή αυτή διαχειρίζεται αποτελεσματικά βαριά φορτία εργασίας, καθιστώντας την ιδανική για έργα καρφώματος μεγάλης κλίμακας.

Ο σχεδιασμός της μηχανής διευκολύνει τη βέλτιστη απόδοση, εξασφαλίζοντας την ακριβή παραγωγή νυχιών και τη διατήρηση της σταθερής ποιότητας. Η ικανότητά του να αυτοματοποιεί διάφορες διαδικασίες όχι μόνο επιταχύνει την παραγωγή αλλά μειώνει επίσης το ανθρώπινο λάθος, οδηγώντας σε σημαντική εξοικονόμηση χρόνου και βελτίωση της παραγωγής. Με την ενσωμάτωση αυτού του μηχανήματος στις εργασίες σας, μπορείτε να επιτύχετε αυξημένη αποτελεσματικότητα και αξιοπιστία στις εργασίες παραγωγής νυχιών.

Συχνές Ερωτήσεις

Τι είναι ο εξοπλισμός Ky Nailing;

Ο όρος "εξοπλισμός καρφιάς" αναφέρεται σε εξειδικευμένα εργαλεία που χρησιμοποιούνται στην κατασκευή και τη ξυλοτεχνία για την ακριβή και ασφαλή έλξη καρφιών σε διάφορα υλικά.

Γιατί η συντήρηση είναι σημαντική για την Ky Nailing Equipment;

Η συντήρηση είναι ζωτικής σημασίας για την εξασφάλιση της μακροζωίας και της αποτελεσματικότητας των εξοπλισμού Nailing Ky. Η κατάλληλη συντήρηση αποτρέπει την ταχεία φθορά, την βλάβη των εξοπλισμών και τις δαπανηρές επισκευές.

Ποια είναι τα κοινά προβλήματα με το Ky Nailing Equipment;

Συνήθως τα προβλήματα περιλαμβάνουν μπλοκάρισμα, ασταθές βάθος νυχιών και διαρροές αέρα. Τα προβλήματα αυτά μπορούν να επηρεάσουν την επιχειρησιακή αποτελεσματικότητα και θα πρέπει να αντιμετωπιστούν άμεσα.

Ποια προϊόντα βελτιώνουν τις επιδόσεις του Ky Nailing Equipment;

Η αυτόματη πνευματική μηχανή κατασκευής νυχιών Brad είναι σημαντική για την ενίσχυση της απόδοσης, προσφέροντας εξορθολογισμένες λειτουργίες και μειώνοντας τη χειρωνακτική εργασία σε μεγάλα έργα.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ