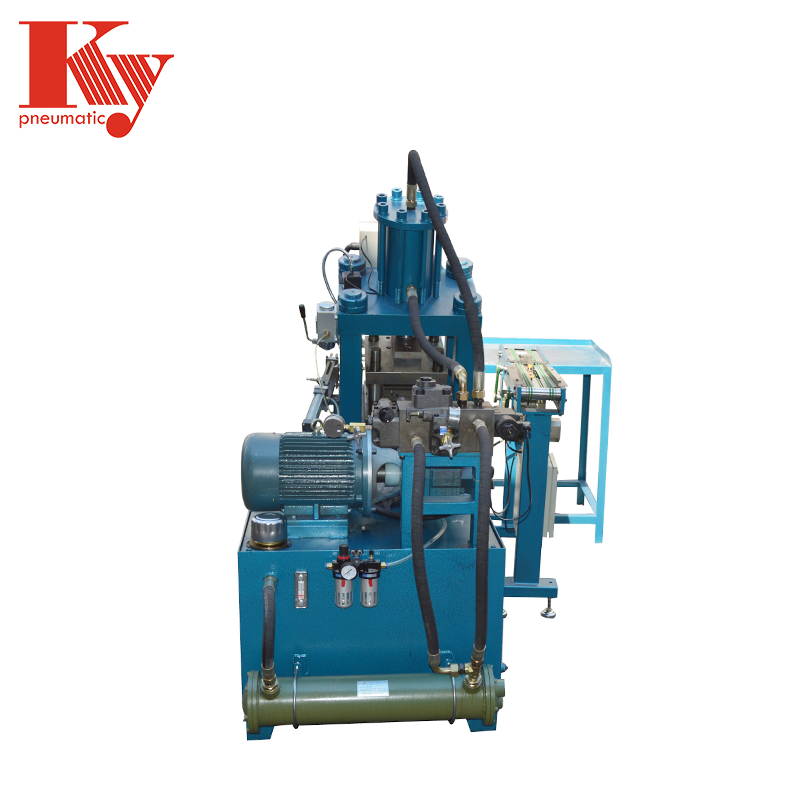

Fine Wire Staple Making Machine

- Introduction

Introduction

Fine wire staple making machine adopts high pressure oil circuit, low noise, less failure rate, the circuit adopts PLC integrated control, the product infinite limit, exquisite production. Equipped with extended conveying equipment, it can automatically pick up staples with high degree of automation, which can reduce staple pickers and reduce production costs.

To press and form the wire band to the final product staples. This machine has abandoned the traditional heavy punch press, adopting the hydraulic system as the executive part, utilizing the PLC system, which has the characteristics of safe operation, stable performance, low noise and so on. Compared with the traditional punch machine, the speed is greatly increased.

We provide two solutions for our customers.

1.wire band + wire straightening machine+ fine wire staple making machine

2.wire flattening machine + wire gluing machine + wire straightening machine + fine wire staple making machine

Advantages:

1.Adopt PLC automatic control, people can choose manual, semi-automatic, automatic production.

2.The length of nails can be adjusted,and the error range of feeding length is 0.1mm.

3.Equipped with the automatic packing arrangement machine,reduce the labor intensity of packing workers.

4.Automatic production speed: 100-160 pieces/minute, speed can be adjusted.

5.The machine is equipped with automatic lubricating oil supply system to ensure the life of the mold.

6.Mold are made of special materials, stable and durable.

7.The machine has automatic protection device, current overload protection, overload power off protection and other functions.

After-sales service: We can provide product instructions, machine debugging videos.You also can add our engineer WeChat group to ask for solutions ,and even we supply oversea service to appoint our engineer to the customers' factory for debugging the machines.

ITEM NO.:KY-008

PRODUCT NAME: Fine Wire Staple Making Machine

MOTOR POWER: 380V, 3 Phase, 50Hz, 5.5KW

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ