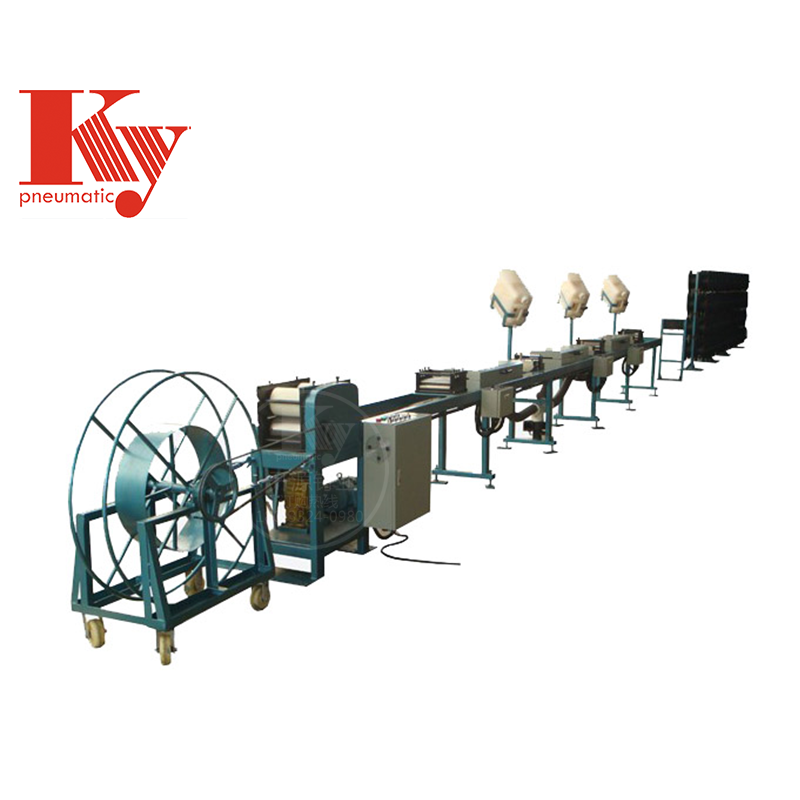

Highly Automated Multiple Staple Iron Wire Band Forming, Gluing and Staple Production Line Machine for 100 to 10J Gauge Wires with Enhanced Efficiency up to 80 Pieces per Minute - Comprehensive Full Cycle Wire Band Manufacturing Solution

- Introduction

Introduction

This wire belt machine uses innovative electromagnetic heating technology to process iron wire into wire belts, significantly improving the safety and efficiency of the entire production line. With this latest electromagnetic heating device, energy consumption can be reduced by more than 70% compared to traditional heating methods. In addition, the glue mold on the equipment adopts upgraded technology, which greatly reduces the amount of glue used.

One of the highlights of this wire belt machine is that it uses the latest electromagnetic heating technology, which can be called a milestone in production line innovation. Compared with traditional heating methods, electromagnetic heating technology not only provides a more efficient and precise heating process, but also greatly enhances the safety of wire bonding operations. This advancement ensures even control and precise application of heat, minimizing the potential risks associated with traditional heating methods.

Advantages and features:

1. Using electromagnetic heating technology, it saves up to 80% of electricity compared to ordinary heating methods.

2. By using electromagnetic heating, fire risks are avoided and safety production performance is improved.

Motor Specifications: Dual 3.0KW Motors, Operates on a 380V, 3-Phase System with a Frequency of 50Hz

Machine Weight: Total Mass is 1000 Kilograms

Machine Dimensions: Measures 20 meters in Length, 0.5 meters in Width, and stands at a Height of 1.8 meters Wire Band

Formation Width: Capable of Forming Bands up to 150 millimeters

Wide Production Rate: Adjustable Speed from 0 to 20 meters per minute

PRODUCT:Wire Band

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ