Šernų žiedų mašina: specialių formų segtukų gamyba

Supratinkimas apie kiaulinių ženklų mašinas

Kiaulinių ženklų mašinos yra specializuoti įrenginiai, naudojami medžiagoms sujungti kiaulinių ženklų pagalba, kurie yra galingi jungikliai, panašūs ant stabinėlių. Wiračių stabinėlių mašinos, naudojančios plonius, skardus stabinėlius, skiriasi nuo kiaulinių ženklų mašinų, kurios sukurtos aptarnauti stipresnius, trikampius ar apvalius ženklus iš ilgalaikių medžiagų, tokios kaip geležis. Toks konstravimas leidžia joms tvirtai sujungti sunkias tekstilines gamas, gardą ar dekoraciją, dėl ko jos yra neatsiejamos automobilių, baldų gamyboje ir agricultūroje pramonėse.

Funkcijų hog ring mašinų veikimo yra sudėtingi mechanizmai, leidžiantys joms formuoti ir fiksuoti šiuos unikalius skrbliukus. Jos veikia suderindamos hog rings ir sutrumpinant juos aplink medžiagas, kurias reikia sujungti, dažnai naudojant pneumatinią technologiją, kad padidintų efektyvumą ir tikslumą. Sužlegtis užtikrina, kad hog rings tvirtai fiksuotų, o kartais naudojamos varžymo technikos, kad stiprintų ryšį. Šis sudėtingas procesas leidžia hog ring mašinoms sukurti galingus ryšius, kurie išlaiko didelę slaptuvą ir deformaciją, atskiriant jas nuo konvencinių skrbliuko įrenginių.

Pagrindiniai naudoties naudos naudojant hog ring mašinas gamybai specialaus formato skrbliukams

Hog ring mašinos dideliose mastuose padidina gamybos efektyvumą specialios formos stulpelių gamyboje. Šios mašinos siūlo nuostabus išmetamumo rodiklius, kurie viršija tradicinius rankinio darbo metodus. Pavyzdžiui, automatizacija, teikiamoji hog ring sistemomis, gali drastiškai sumažinti darbo išlaidas, nes mažiau operatorių reikalinga įrenginiu valdymui. Šis padidėjęs efektyvumas leidžia greičiau gaminti ir patenkinti griežtas terminų reikalavimus, dėl ko hog ring mašinos yra nematomos aukštos paklauso aplinkose.

Be tobulumoje, šunų žiedų mašinos yra nuostabiai daugialypios ir randamos įvairiose pramonės šakose. Šios mašinos yra būtinos pet produkto gamyboje, baldų montavime ir pakrovimo pramone. Pet produktų pasaulyje, pavyzdžiui, šunių žiedai naudojami kandelių ir transportuoklių sudarymui. Baldų pramonėje jie yra neatsiejami dekoratyviniam tapetui fiksuoti, užtikrinant, kad produktai būtų tvirti ir estetiškai patraukliai. Tarpusavyje, pakrovimo srityje, šunų žiedai padeda uždengti maišelius, ypač jungiant su drabužių tempimo mašinomis. Ši daugialypumas užtikrina, kad įmonės iš skirtingų sektorių gali naudoti šias mašinas, kad stiprintų savo gamybos galimybes ir laikytų aukštos kokybės standartus.

Skirtingi šunų žiedų mašinų tipai

Švinies jungiklio prietaisai yra skirtingų tipų, o rankinės ir pneumatinės versijos yra populiariausios. Rankiniai švinies jungiklio prietaisai reikalauja fizinio pastangos ir tinka mažesniems užduotims arba tuo atveju, kai nėra elektros. Pneumatiniai prietaisai naudoja sušlaminą oro, teikiant pranašumus greičio ir veiklos sutelkumo požiūriu. Šie automatizuoti prietaisai gali didelių mastų padidinti gamybos tempą ir sumažinti darbuotojų išsiganda, todėl jie yra idealūs aukštos apimties operacijoms, kur efektyvumas yra svarbus.

Kartu su rankiniais ir pneumatikiniais, yra specializuotų kiaulinių žiedų mašinų, kurios atitinka konkrečias gamybos reikalavimus. Šios mašinos dažnai turi deramų nustatymų, leidžiančių gamintojams tvarkyti įvairius skrblių formų ir dydžių, pavyzdžiui, C-, D- ir M-formos žiedus. Ši suderinamumas yra būtinas pramonėms su įvairiais fiksavimo reikalavimais, užtikrinant verslumą ir tikslumą gamyboje. Pasirinkę tinkamą mašiną, verslai gali optimizuoti savo fiksavimo procesus ir atitikti konkrečias pramonės normas.

Produkto apžvalga

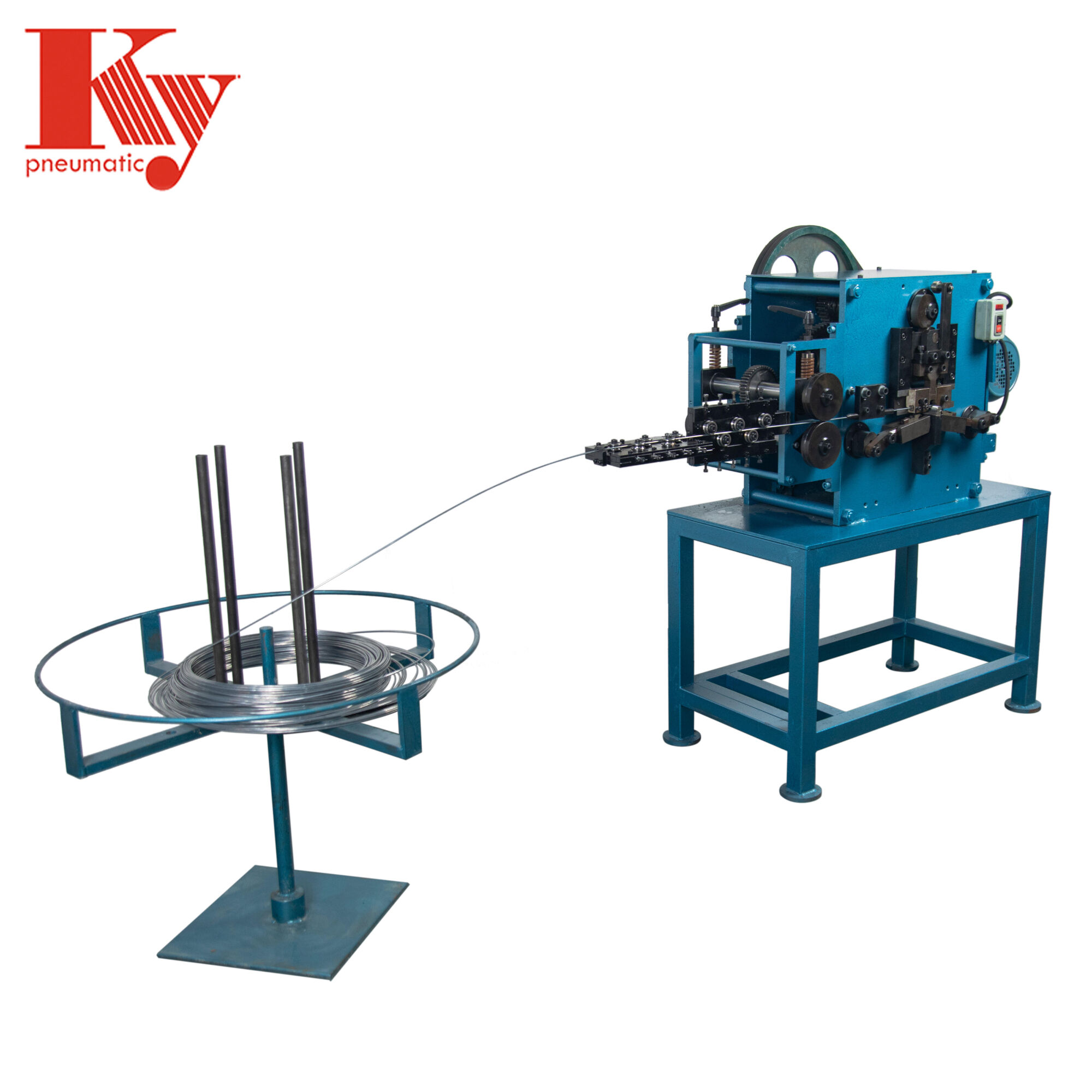

Šaltinio rinkimo mašina yra daugiafunkcinis įrankis, kuris efektyviai paverčia apvalią drąsą finišuotais produktais su minimaliu triuku ir aukšta stabilumu. Ji ypač tinka pramonės sričiams, reikalaujančioms tikslumo, įskaitant miestelių kandolių gamybą, automobilių dalių ir baldų gamybos. Ši mašina leidžia vienam operatoriui kartu valdyti iki penkis aparatus, pažymindama savo efektyvumą pramoniniuose aplinkose. Ji yra apjungta su automatiniais skaičiuokliais, pjovimo prietaisais ir ištiesimo bloku, užtikrinančiais tikslius rezultatus.

Stogų ženklų gaminti mechanizmas yra sukurtas, kad apimtų visą gamybos procesą nuo dratio iki baigtinio stogo ženklo, siūlydamas stiprią našumą su mažu triukšmu. Šis aparatas yra plačiai naudojamas gamindami gyvūnų kabinės, mobiliojo ir automobilių komponentus dėl tikslios temperatūros kontrolės ir automatinio funkcijų, kurie padidina našumą ir tikslumą pramoniniuose taikymuose.

Stogų ženklų gaminių taikymai įvairiose pramonės šakose

Švinies montavimo prietaisai turi daugybę panaudojimo sritybių įvairiose pramonėse, dėl ko jie yra universali įrankis gamintojams ir dirbėjams vienodai. Medžiagų audiniuose, skirtuose gyvūnų kabinėms, šie prietaisai yra būtini, kad pagerinti kabinių saugumą ir ilgalaikį naudojimą. Šviniai veikia kaip griežti fiksatoriai, sujungiantys metalines lizdas ir tinklus, užkertantys jų atskyrimo ar tarpų, kurie galėtų pavojingai paveikti gyvūnus, galimybę. Ši funkcija yra labai svarbi, nes ji užtikrina, kad kabins būtų stiprios ir ilgaamžios, teikiant saugų gyvūnams aplinką.

Furnitūros gamybos srityje švinies jungiklių mašinos žaidžia svarbų vaidmenį struktūrų montavime ir tapetų fiksuojime. Šios mašinos naudojamos norint prifiksuoti tapetės audinį prie medienos ar metalo rėmimo, užduotyje, kurioje paprasti klijučiai gali nesugebėti. Švinies jungiklių dizainas, su jų švelnais gausiais ir jėginiu konstravimu, leidžia jums lengvai įsišokti per sunkias medžiagas, užtikrinant, kad audinys liks įtemptas ir saugus ilgo laikotarpio metu. Tai ne tik patobulina furnitūros išvaizdą, bet ir išilgina jos gyvavimo trukmę, palaikydama tapetės integritetą.

Teisingas švinies jungiklių mašinos pasirinkimas

Pasirinkimas optimalaus kiaušinių apdirbimo aparato yra svarbus gamybos eilutės optimizavimui. Nusprendžiant dėl pirkimo, turėkite omenyje veiksnius, tokius kaip gamybos apimtis, kiaušinių formos ir biudžeto apribojimai. Didelėms gamybos operacijoms naudingi aparatai, kurie gali pritaikyti įvairias kiaušinių formas ir matmenis, užtikrinant universalią ir efektyvią naudojimą. Biudžeto apribojimai gali riboti aukštos klasės modelių pasirinkimą, tačiau svarbu suderinti kainą su funkcionalumu, kad išvengti ateityje galimų našumo apribojimų.

Norėdami efektyviai įvertinti gamybos poreikius, verslui reikia taikyti struktūrizuotą vertinimo metodą. Pradėkite analizuodami esamus ir tikimarus gamybos reikalavimus, atsižvelgdami į tokias aspektus kaip apdorojamų medžiagų tipai ir naudojimo dažnumas. Išsiskelbkite šiuos poreikius ir palyginkite juos su galimybėmis turimų kiaulienų žiedų mašinų. Svarbiausių individualizuotų funkcijų prioritetavimas ir produktų specifikacijų konsultavimas gali padėti priimti sprendimą, kuris maksimaliai prisidėtų prie operacinio naudingumo. Tokiu metodu pramone gali užtikrinti, kad pasirinkta kiaulienų žiedų mašina tinkamai atitiktų jų gamybos poreikius.

Miesto žiedų mašinų technologijos ateities tendencijos

Pramonė, gaminančią kiaulienų žiedus, stebi didelės inovacijos, ypač medžiagų ir modeliavimo technologijų srityse. Šios inovacijos pagerina kiaulienų žiedų išsigyvenamumą ir funkcionalumą, leidžiant jų naudoti sudėtingesniuose pritaikymuose. Pavyzdžiui, stipriųjų ligavinių ir sluoksnio taikymas gali padidinti trikdžių varžymo išlaikymo gebėjimą bei ilgalaikį naudingumą, o tai prisideda prie ekonomiškumo ilgą laikotarpį.

Automatizavimas žaidžia svarbų vaidmenį didinant gamybos efektyvumą kiaulienų žiedų gamyboje. Nauja studija nurodė, kad daugiau nei 60 % gamintojų pritraukė automatizavimo technologijas, dėl kurių gamybos apimtis padidėjo maždaug 20 %. Kai pramonė tobulėja, robotikos ir dirbtinio intelekto pagrįstų prietaisų integracija turėtų dar labiau supaprastinti operacijas, sumažinti žmogiškus klaidas ir sumažinti eksploatacijos išlaidas, pažymindama transformacinį pokytį tuo, kaip kiaulienų žiedai gaminiama ir pritaikomi įvairiose sektoriuose.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ