Maszyna do wytwarzania zestawów: precyzyjne i wydajne narzędzie produkcyjne

Ważność wydajnych maszyn do produkcji spinaków w przemyśle

Wydajne maszyny do produkcji spinaków odgrywają kluczową rolę w różnych sektorach przemysłu, takich jak pakowanie i meblarstwo, oferując szybkie i niezawodne rozwiązania do łączenia materiałów. Te maszyny są centralne w operacjach, gdzie masowe produkowanie przedmiotów przymocowywanych spinakami jest kluczowe, zapewniając spójne i bezpieczne łączenie produktów, od kartonowych pudełek po tapicerki. W miarę jak branże dążą do skrócenia czasu produkcji i poprawy jakości wyrobów, znaczenie maszyn do spinaków staje się coraz bardziej widoczne.

Funkcjonalność maszyn do produkcji spinaków została zaprojektowana tak, aby spełniać wymagania wysokoszybkiej produkcji bez kompromitowania jakości. Korzystając z zaawansowanych technologii, takich jak kontrola PLC i systemy hydrauliczne, nowoczesne maszyny do produkcji spinaków, takie jak Automatyczna Maszyna do Produkcji Spinaków Typu Gwoździk osiągnąć większą wydajność i stabilność, jak podkreślono w Treści Referencyjnej. Te maszyny eliminują potrzebę ciężkich metod bicia, oferując tym samym bezpieczniejsze działania, zmniejszone poziomy hałasu i poprawioną wydajność.

Ponadto, integracja automatyzacji w maszynach do produkcji spinaczy zwiększa ogólną wydajność produkcyjną, redukując koszty pracy i minimalizując błędy ludzkie. Ta automatyzacja umożliwia ciągłą produkcję przy minimalnym udziale człowieka, zapewniając płynny cykl operacyjny. W wyniku tego, producenci mogą skupić się na skalowaniu swoich działań i utrzymywaniu wysokich standardów jakości produktów, co ostatecznie prowadzi do większej rentowności i zadowolenia klientów. Automatyzacja w tych maszynach jest więc kluczowym czynnikiem w optymalizacji procesów produkcyjnych w różnych przemyślach.

Kluczowe funkcje efektywnych maszyn do produkcji spinaczy

Dokładność i kontrola są podstawowymi atrybutami współczesnych maszyn do produkcji szpilek, zapewniając spójne i precyzyjne parametry produkcyjne. Zaawansowana technologia w tych maszynach jest kluczowa do spełnienia wysokich wymagań co do dokładności, która jest istotna w różnych sektorach produkcyjnych, od meblarskiego po budowlany. Dzięki zastosowaniu technologii precyzyjnej, producenci mogą osiągnąć jednolitą produkcję szpilek spełniającą surowe standardy jakości, co zwiększa ogólną wydajność ich działań.

Niski poziom hałasu w maszynach do produkcji szpilek to kolejna ważna cecha, która pozytywnie wpływa na warunki pracy w zakładzie produkcyjnym. Zgodność z normami hałasowymi jest kluczowa dla przestrzegania przepisów zdrowotnych i utrzymania produktywności pracowników. Nowoczesne maszyny są projektowane z funkcjami tłumiącymi dźwięk, które redukują zakłócenia dźwiękowe, zapewniając cichsze miejsce pracy, które nie tylko jest bardziej wygodne, ale również przyczynia się do lepszych wyników zdrowotnych operatorów w dłuższej perspektywie.

Wysoka efektywność tych maszyn znacząco wpływa na koszty operacyjne, przekładając się na niższe zużycie energii i zwiększoną wydajność. Optymalizując użycie prądu, producenci mogą obniżyć rachunki energetyczne, jednocześnie zwiększając tempo produkcji. Efektywne maszyny stanowią więc opłacalne rozwiązanie, które wzmacnia zyskowność w dłuższej perspektywie. Na przykład, maszyny jak Maszyna do Produkcji Skrawków Serii J nie tylko mają wydajność dzienną dochodzącą do 1000 kg, ale również działają z pomniejszonym zapotrzebowaniem na energię.

Statystyki wskazują, że maszyny do produkcji szpulek ułatwiają masową produkcję, efektywnie obniżając koszty operacyjne. Badania pokazują, że zaawansowane maszyny mogą zmniejszyć koszty pracy o do 30% dzięki swoim możliwościami automatycznym, które minimalizują błędy ludzkie i przyspieszają procesy produkcyjne. Taki rodzaj inwestycji w nowoczesne maszyny do szpilek dotyczy nie tylko natychmiastowych oszczędności finansowych, ale również długoterminowej zrównoważoności i konkurencyjnej przewagi na rynku. Dzięki pozostawaniu w trendzie z najnowszymi maszynami, producenci mogą zapewnić sobie pozostanie na czele swojego sektora.

Typy maszyn do produkcji szpilek

Maszyny do produkcji spinaków są dostępne w różnych typach, każdy z nich odpowiada konkretnym wymaganiom i zastosowaniom przemysłowym. Maszyny do produkcji spinaków z cienkiego drutu są projektowane do zadań wymagających delikatnego i precyzyjnego przykręcania, takich jak w przemyśle tekstylnym lub elektronicznym. Te maszyny oferują zwiększoną precyzję dzięki swojemu specjalistycznemu konfigurowi, co zapewnia minimalne uszkodzenie wrażliwych materiałów.

W przemyślach takich jak pakowanie, maszyny do produkcji spinaków do zamykania kartonów są niezastąpione. Są one mocne, zaprojektowane do obsługi operacji o dużym obrocie, i zapewniają bezpieczne zaklejanie pudeł i kontenerów. Ich solidna konstrukcja jest idealna dla zastosowań ciężkich, czyniąc je niezbędne w centrach logistycznych i dystrybucyjnych.

Maszyny do produkcji spinaków klipsowych do materaców skupiają się na przemyśle meblarskim. Są one dopasowane do efektywnego produkowania klipsów, zapewniając szybkie montowanie i trwałą jakość materaców. Te maszyny zwiększają produktywność i zapewniają spójność wyjściową, wspierając linie masowej produkcji.

Dla aplikacji wymagających mocnego przykręcania, maszyny do produkcji śrub z wysokowęglowego stali są bardzo odpowiednie. Słyną ze swojej trwałości, te maszyny mogą radzić sobie z trudnymi materiałami dzięki sile przekazywanej przez stal węglową. Zapewniają niezawodną pracę w wymagających środowiskach, takich jak budownictwo.

Maszyny do produkcji śrub z napędem serwospindletem integrują automatyzację, aby zwiększyć wydajność. Dzięki ich zaawansowanej technologii, te maszyny oferują poprawioną prędkość i dokładność, zmniejszając manualne działania i błędy. Ta automatyzacja oznacza wyższą efektywność w produkcji śrub, odpowiadając potrzebom branży wymagającej szybkiego przepływu bez kompromitowania jakości.

Przewagi wynikające z użycia efektywnej maszyny do produkcji śrub

Korzyści wynikające z korzystania z wydajnego urządzenia do produkcji spinaków są głębokie, zaczynając od wyższych temp produkcji, które spełniają popyt konsumentów szybciej. Poprzez optymalizację procesów produkcyjnych, przedsiębiorstwa mogą znacząco poprawić swoje łańcuchy dostaw, co prowadzi do bardziej niezawodnej i punktualnej dostępności produktów na rynku. Ta zdolność do szybkiego produkowania dużych objętości gwarantuje, że firmy nigdy nie odpadną za harmonogramami konkurencji, co pozwala utrzymać zaufanie klientów. Na przykład, wprowadzenie maszyn do produkcji spinaków w linii produkcyjnej meblarskiej przyczyniło się do zwiększenia wydajności o 30%, jak podano w badaniu przeprowadzonym przez Stowarzyszenie Efektywności Produkcji w 2023 roku.

Poprawa kosztów jest kolejnym istotnym vantagem, osiągniętym dzięki niższym kosztom pracy i zmniejszonemu marnowaniu materiałów. Automatyzacja redukuje potrzebę rąk roboczych, obniżając koszty eksploatacyjne jednocześnie optymalizując wykorzystanie materiałów. Na przykład, maszyna do przybijania śrubek stosowana w pakowaniu może minimalizować marnowanie materiału drutu, zapewniając, że każda śrubka jest precyzyjnie wyprodukowana i zmniejsza nadmiernego użycia. Integracja efektywnych maszyn spowodowała, że firmy w przemyśle tekstylnym zgłosiły oszczędności do 25% na kosztach materiałów, jak opublikowano w Journal of Industrial Manufacturing.

Poprawa jakości produktu jest kluczowym beneficją związaną z użytkowwanie zaawansowanych maszyn do produkcji scieżek, ponieważ zapewniają one precyzję w każdym produkowanym scieżku. Ten poziom dokładności przekłada się na zwiększone zadowolenie klientów, co z kolei redukuje liczbę zwrotów produktów. Dzięki niezawodnym maszynom do scieżek margines błędu znacząco maleje, oferując bardziej spójny produkt końcowy użytkownikom końcowym. Badania branżowe wykazują, że firmy korzystające z nowoczesnych maszyn zgłaszają wzrost o 15% w ocenie zadowolenia klientów.

Na koniec, opinie ekspertów i statystyczne dane potwierdzają ogólną wydajność efektywnych maszyn w porównaniu z metodami tradycyjnymi. Różne raporty wskazują, że maszyna do produkcji scieżek działa z wydajnością do 90% większą w porównaniu do starszych modeli maszyn. Takie postępy obiecują nie tylko doskonałość operacyjną, ale również długoterminową rentowność dzięki dostarczaniu lepszych produktów w niższej cenie i w szybszym tempie.

Eksploracja różnych modeli maszyn do produkcji scieżek

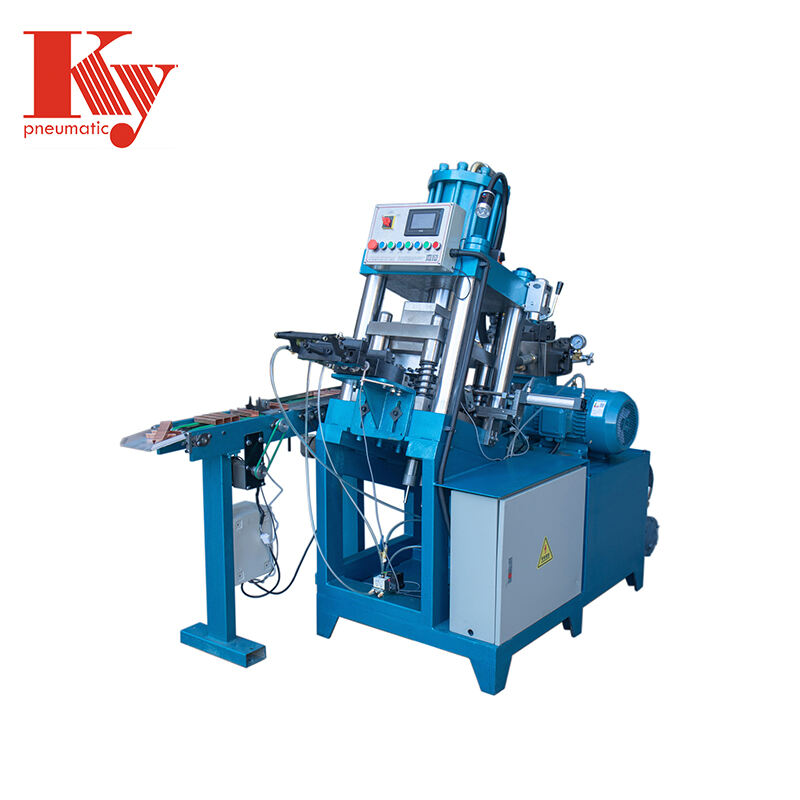

The maszyna do wytwarzania sztapowych drutów wyróżnia się swoją precyzją i wielofunkcyjnością, co jest kluczowe dla branż wymagających wysokiej jakości produkcji śrub. Ten aparat jest wyposażony w zaawansowane funkcje, takie jak sterowanie zintegrowane PLC i rozszerzone urządzenia transportujące do automatyzacji, co redukuje pracę ręczną. Zastosowanie układu hydraulicznego zapewnia stabilność działania i niski poziom hałasu, czyniąc go idealnym rozwiązaniem dla sektorów wymagających precyzji i efektywności w produkcji śrub.

Gdy chodzi o rozwiązania pakownicze, 32/35/34 Maszyna do tworzenia kartonów do zamykania sztapu cieszy się mocną obecnością na rynku dzięki swojej niezawodności i efektywności. Ten model jest chwalony w recenzjach użytkowników za zmniejszenie obciążenia pracowników i zoptymalizowanie produkcji dzięki automatycznym układom pakowania. Jest specjalnie zaprojektowany do produkcji śrub kartonowych, balansując prędkością z efektywnością operacyjną.

The maszyna do tworzenia zacisków materacowych jest zaprojektowany z użyciem najnowszych technologii, jednak napotyka na pewne wyzwania operacyjne notowane w opinii użytkowników. Podczas gdy system dopływu jest stabilny i oszczędza energię, niektórzy podnoszą problem złożoności początkowego uruchomienia. Mimo to, jego wysoka dokładność w produkcji form oraz użycie trwałych materiałów czyni go liderem w przemyśle materacowym, zapewniając niezawodne dostawy klinów dla zastosowań ciężkich.

Trwałość jest kluczową siłą maszyn do produkcji klinów z zakalanej stali carbonowej podobnie jak model 4K. opinie użytkowników wskazują, że wytrzymuje długo i wymaga minimalnego utrzymania, co czyni go ulubionym wyborem dla branż potrzebujących solidnych połączeń, takich jak produkcja mebli. Jego funkcje, takie jak automatyczne wyprostowywanie i cięcie gwoździ, zapewniają precyzję i zmniejszają wysiłki związane z konserwacją ręczną.

Wreszcie, maszyny do produkcji klamer z napędem serwospinającym osiągnęły istotne postępy w nowoczesnych środowiskach produkcyjnych. Ich ulepszona technologia eliminuje potrzebę źródeł powietrza, oferując ciche, wydajne działanie z niskim zużyciem energii. Użytkownicy doceniają łatwą nawigację przez ekran dotykowy, co wzmacnia prostotę i dokładność operacji przy dużych objętościach produkcji klamer.

Wspólnie te maszyny odzwierciedlają przesunięcie w przemyśle w kierunku zaawansowanych technologicznie, wydajnych i ergonomicznych metod produkcji, które odpowiadają konkretnym potrzebom przemysłowym, zapewniając zrównoważoną i wysokiej jakości produkcję śrub.

Przyszłe trendy w technologii produkcji śrub

Integracja inteligentnych technologii, zwłaszcza IoT i automatyzacji, rewolucjonizuje maszyny do produkcji śrub, poprawiając efektywność operacyjną. Te systemy umożliwiają monitorowanie w czasie rzeczywistym, predykcyjne konserwacje i automatyczne dostosowania, zmniejszając simplyfikację procesów produkcyjnych, obniżając koszty i zwiększając precyzję w produkcji śrub.

Ponadto, praktyki zrównoważonego rozwoju stają się coraz bardziej kluczowe w produkcji śrub, przy czym branża przesuwa się w kierunku materiałów i procesów przyjaznych środowisku. Producenci inwestują w odnawialne zasoby i recyklingowe materiały, aby zmniejszyć wpływ na środowisko. Ten ruch odpowiada na rosnące zapotrzebowanie konsumentów na produkty ekologiczne i jest zgodny z globalnymi celami zrównoważonego rozwoju.

Ponadto, obecne wymagania rynkowe wykazują rosnący interes wobec innowacyjnych śrub, zachęcając producentów do zmiany strategii i utrzymania konkurencyjności. Raporty badawcze wskazują na wzrost popytu na unikalnie zaprojektowane śruby, które są dedykowane konkretnym branżom, takim jak motoryzacyjna i meblarska. W związku z tym, producenci badają nowe materiały i techniki, aby produkować śruby spełniające te zmieniające się potrzeby, podkreślając wielofunkcyjność i wysoką wydajność swoich ofert produktówych.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ