Estabelecida em 2018, a Fábrica de Equipamentos de Grampeamento Dongguan Shilong é um fabricante respeitável especializado em uma variedade de máquinas pneumáticas para grampos e pregos. Com uma sólida expertise técnica e capacidades de produção, temos orgulho de oferecer soluções de alta qualidade.

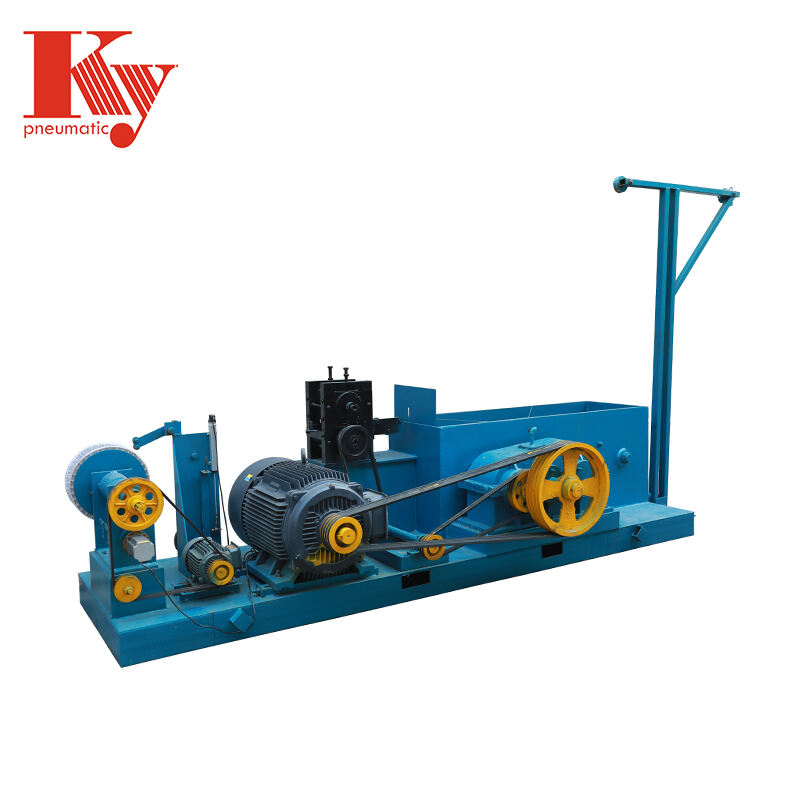

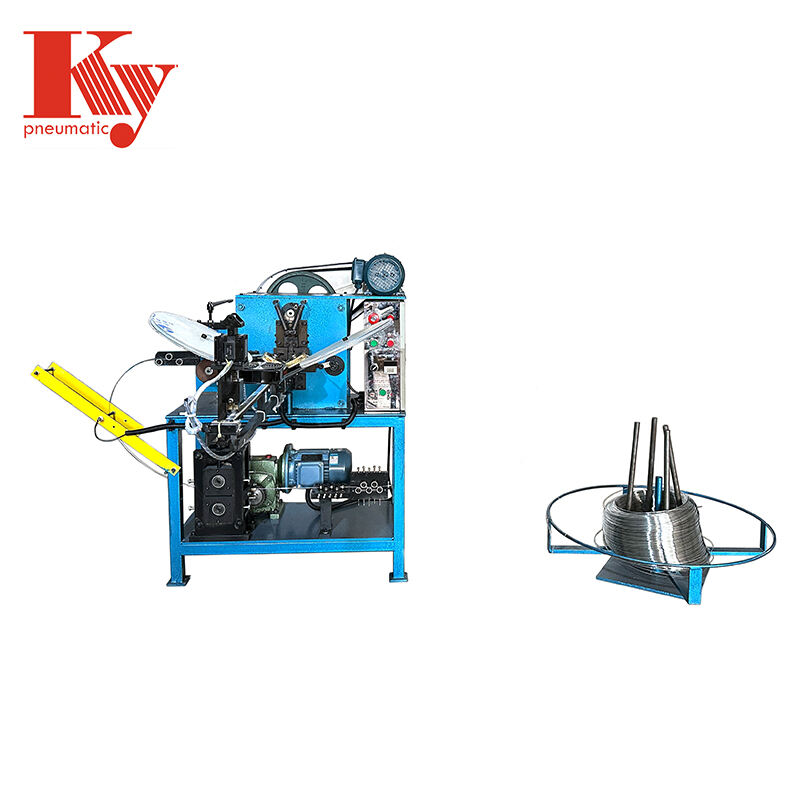

Nossa ampla gama de produtos abrange máquinas para fabricação de grampos e pregos tipo brad, máquinas de desenho de fio, máquinas de achatamento de fio, máquinas de banda de fio, máquinas para fabricação de grampos de fio único (anel de porco, anel C, etc.), máquinas para fabricação de grampos de clipe de colchão e máquinas para fabricação de grampos de aço carbono de alta qualidade 4K(90). Além disso, nossos engenheiros e equipe técnica são especialistas em personalizar máquinas com base nas necessidades específicas dos clientes.

Com anos de dedicação a esta indústria, estabelecemos uma cadeia industrial completa em circuito fechado. Isso nos permite oferecer preços competitivos e garantir a excelência de nossas máquinas. Nossos produtos ganharam popularidade entre os usuários no Oriente Médio, Ásia, África e América Latina.

Sinta-se à vontade para entrar em contato conosco para mais informações. Suas perguntas são calorosamente bem-vindas.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ