Ιδρυμένη το 2018, η Εργοστάσιο Ξυλορροπικού Συσκευασίας Ky στην Dongguan Shilong είναι αξιόπιστος κατασκευαστής που ειδικεύεται σε διάφορες μηχανές πνευματικής παραγωγής καρφιών και καρφιών. Με ισχυρή τεχνική εμπειρία και παραγωγικές δυνατότητες, υπογραμμίζουμε την παροχή υψηλής ποιότητας λύσεων.

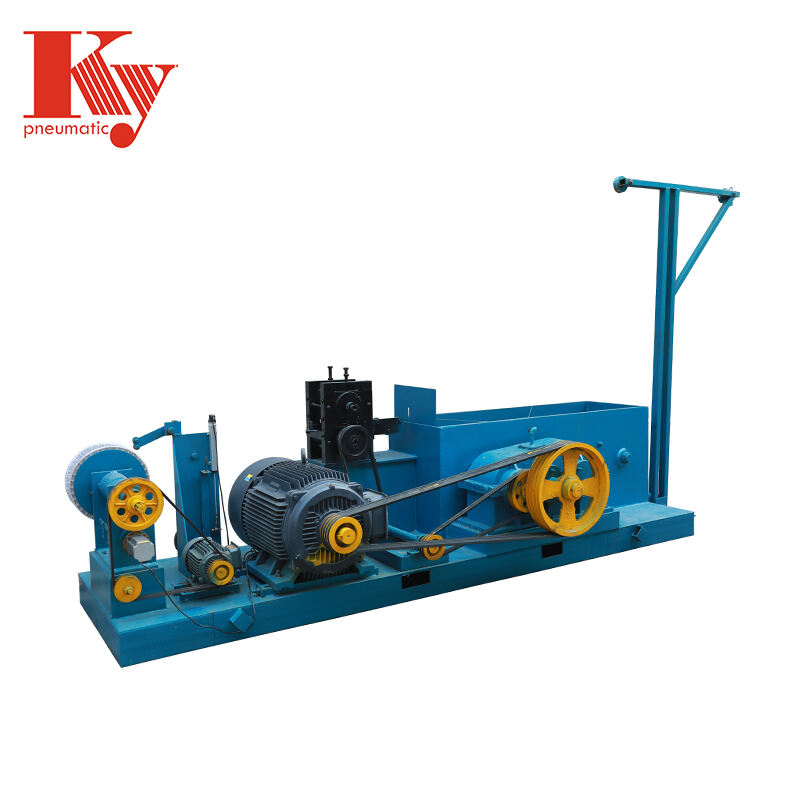

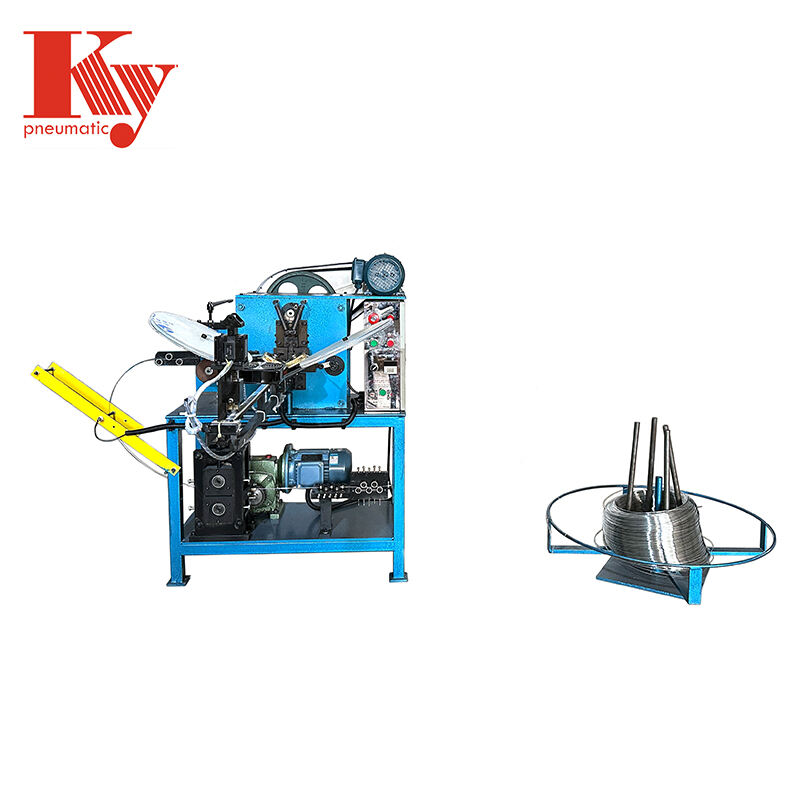

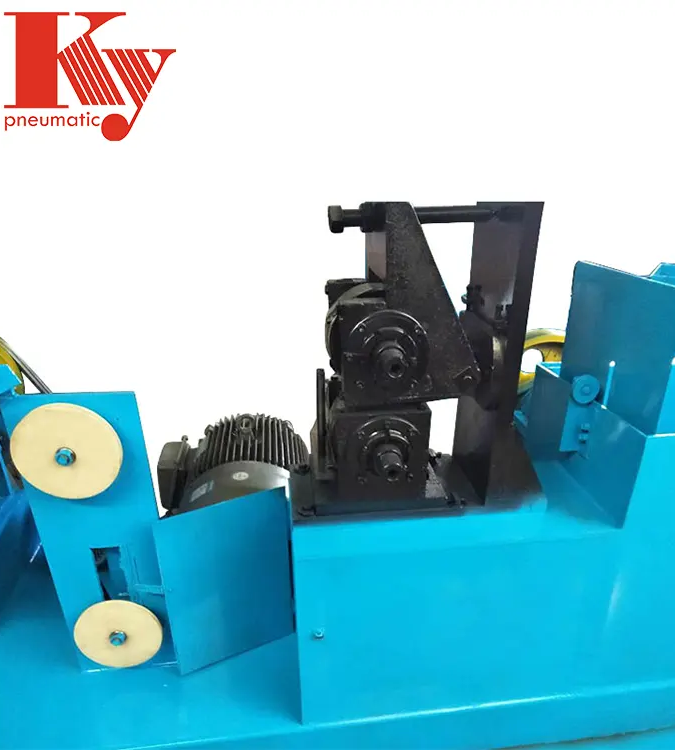

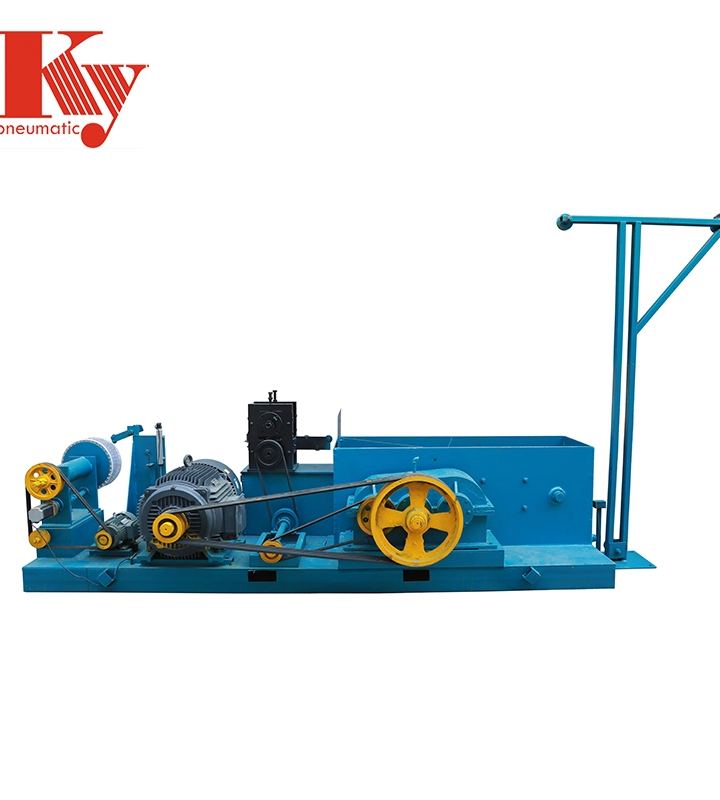

Το εκτεταμένο φάσμα προϊόντων μας περιλαμβάνει μηχανές παραγωγής καρφιών και μικρών καρφιών, μηχανές τενοντού, μηχανές επίπεδης νιτρού, μηχανές νιτρού παλινδρόμησης, μηχανές παραγωγής μικρών καρφιών με μονοκλινές (Hog rings, C ring, κλπ.), μηχανές παραγωγής καρφιών για κρεβάτια, και μηχανές παραγωγής καρφιών υψηλού άνθρακα 4K(90). Επιπλέον, οι έμπειροι μας μηχανικοί και τεχνικοί στελέχωνες εξοικοδομούν μηχανές βάσει των συγκεκριμένων απαιτήσεων των πελατών.

Με χρόνια επιμέλειας σε αυτή τη βιομηχανία, έχουμε δημιουργήσει μια κλειστή συμβολή πλήρως ολοκληρωμένη βιομηχανική αλυσίδα. Αυτό μας επιτρέπει να προσφέρουμε ανταγωνιστικές τιμές και να εξασφαλίζουμε την άψογη ποιότητα των μηχανημάτων μας. Τα προϊόντα μας έχουν κερδίσει δημοφιλεία μεταξύ χρηστών στη Μέση Ανατολή, την Ασία, την Αφρική και τη Λατινική Αμερική.

Να δεν διστάσετε να επικοινωνήσετε μαζί μας για περισσότερες πληροφορίες. Οι ερωτήσεις σας είναι ευπρόσδεκτες.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ