დაარსებული 2018 წელს, დონგუანის შილონგ კაი ნეილინგის აღჭურვილობის ქარხანა არის ცნობილი მწარმოებელი, რომელიც სპეციალიზირებულია სხვადასხვა pneumatic staple და ნAIL-ის დამზადების მანქანებში. ძლიერი ტექნიკური ექსპერტიზით და წარმოების შესაძლებლობებით, ვამაყობთ მაღალი ხარისხის გადაწყვეტილებების მიწოდებით.

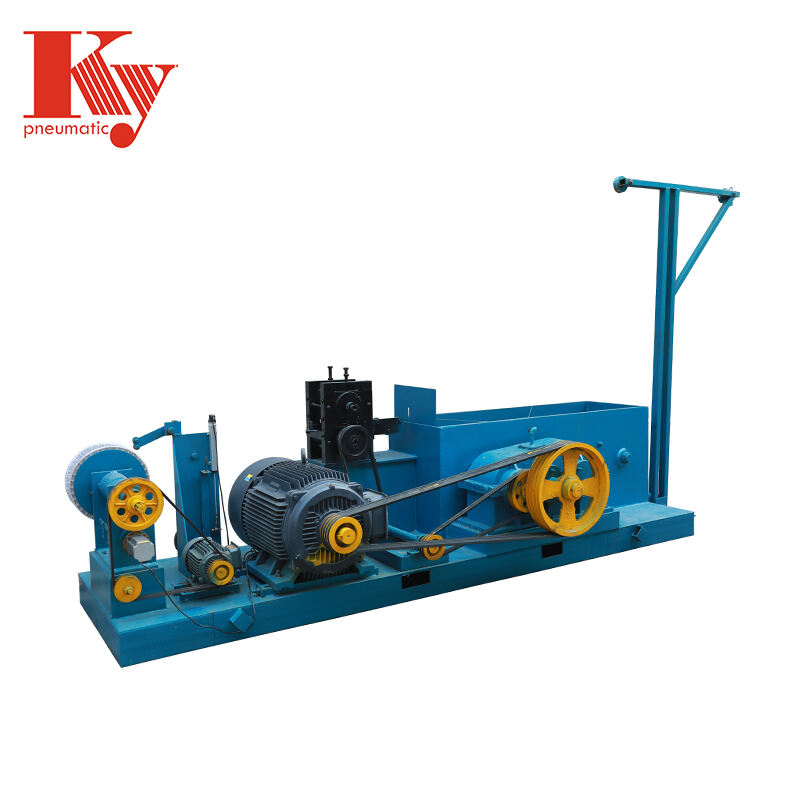

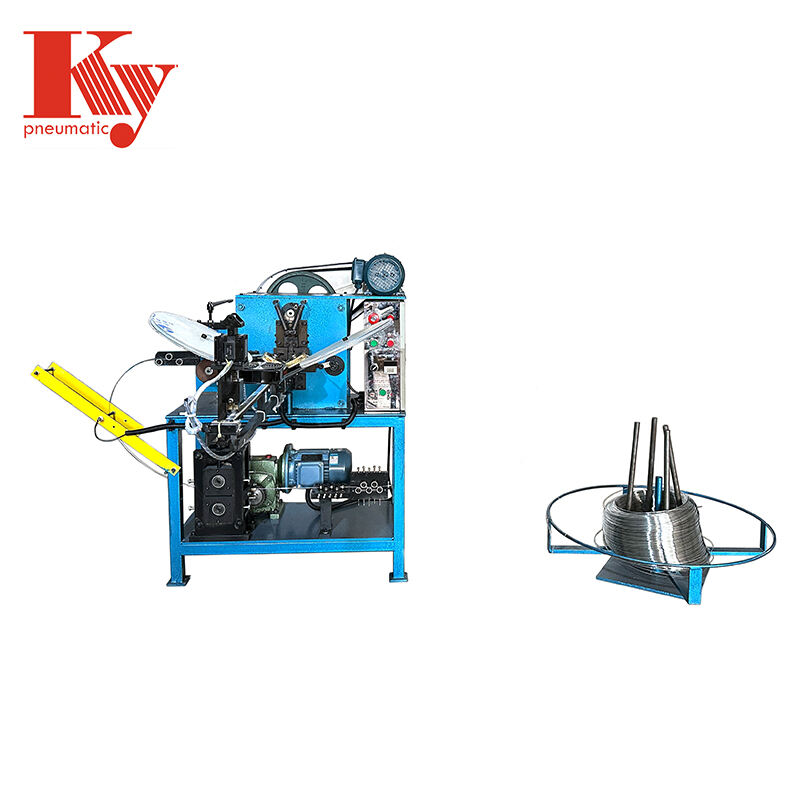

ჩვენი ფართო პროდუქტის ასორტიმენტი მოიცავს სტეპლერების და ბრედ ნAIL-ის დამზადების მანქანებს, მავთულის გაწვდვის მანქანებს, მავთულის გასწორების მანქანებს, მავთულის ბანდის მანქანებს, ერთმავთულა სტეპლერების დამზადების მანქანებს (ჰოგ რგოლები, C რგოლი და ა.შ.), მატრასის კლიპის სტეპლერების დამზადების მანქანებს და 4K(90) მაღალი ნახშირბადის ფოლადის სტეპლერების დამზადების მანქანებს. გარდა ამისა, ჩვენი გამოცდილი ინჟინრები და ტექნიკური პერსონალი გამოირჩევიან მანქანების მორგებით მომხმარებლების კონკრეტულ მოთხოვნებზე.

მრავალი წლის ერთგულებით ამ ინდუსტრიაში, ჩვენ შევქმენით დახურული ციკლის სრული ინდუსტრიული ჯაჭვი. ეს საშუალებას გვაძლევს შევთავაზოთ კონკურენტული ფასები და უზრუნველვყოთ ჩვენი მანქანების ხარისხი. ჩვენი პროდუქცია პოპულარობით სარგებლობს მომხმარებლებში ახლო აღმოსავლეთში, აზიაში, აფრიკაში და ლათინურ ამერიკაში.

გთხოვთ, თავისუფლად დაგვიკავშირდეთ დამატებითი ინფორმაციისთვის. თქვენი კითხვები სიხარულით იქნება მიღებული.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ