The brad nail machine stands as a pinnacle of engineering precision in the woodworking industry, where it has become an indispensable tool for craftsmen and woodworkers. Exclusively designed to adeptly insert slender brad nails into various materials, this sophisticated apparatus embodies efficiency and quality in fastening solutions. Renowned for its versatility and unwavering reliability, the brad nail machine has evolved into an essential tool, elevating the craft of craftsmen and woodworkers alike. Its significance lies not only in its functionality but also in the transformative impact it has had on woodworking methodologies.

The versatility of our brad nail machine allows it to be used in various woodworking applications. This flexibility is what makes it suitable to be used for carpentry, cabinetmaking, and trim work among other uses. In this section, we will examine the many different situations in which our brad nail machine is an outstanding performer that does a fantastic job handling small and minuscule lightweight brad nails with unmatched agility. This is where artisans meet craftsmen who understand why it becomes their preferred tool especially when inconspicuous fastening is more than a choice but a necessity. It can also be described as being useful in several other ways apart from just doing what it was designed to do; that is helping wood workers to accomplish their daily activities in variety of tasks related to wood crafting.

Creativity and design have been merged into our brad nail machine, thereby combining functionality with beauty. Its creation has cost us a lot so that now this device owns an ergonomic shape, which makes it user-friendly for the workers and enhances users’ experience at the same time. For instance, we have added an ergonomic handle that guarantees both secure grip and comfort alongside well-located buttons leading to smooth workflow from beginning to end. This part focuses on how our brad nail machine defies conventionalism by integrating form with function which is why it is so popular with people who like such things. Ours goes beyond a mere machine as it matures into a piece of art signifying a perfect mix of aesthetics and utility.

In order to address the diverse needs of our customers, we have come up with ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) customization options. This section will provide a step-by-step guide on how clients can modify the brad nail machine to fit their specific needs including size adjustments, changes in features or even branding. The idea behind the provision of a range of customization options is so that clients have an opportunity to determine how they want their machines to be built for them. Indeed, by making sure that it matches every craftsman’s/practitioner’s specific demand, our machinery proves itself flexible and therefore all-rounded. It is not only supplying a tool but also offering tailored solutions that best suit individual client vision and aspirations.

The crucial attribute of durability, which is a given in the unforgiving world of woodworking machinery, becomes the main focus as our brad nailer stands above the traditional expectations. This section will go behind the scenes to explain how these devices are built. It will describe the materials used and how they are tested for quality. The argument here is about how it is robust enough to withstand heavy usage, while at the same time being very reliable making it one of its kinds in wood working. In time though, craftspeople understand that our brad gun is not just a tool; it represents forever against all odds and any other form of challenges. This proves beyond any reasonable doubt that we take sustainability and performance seriously in every project that we undertake.

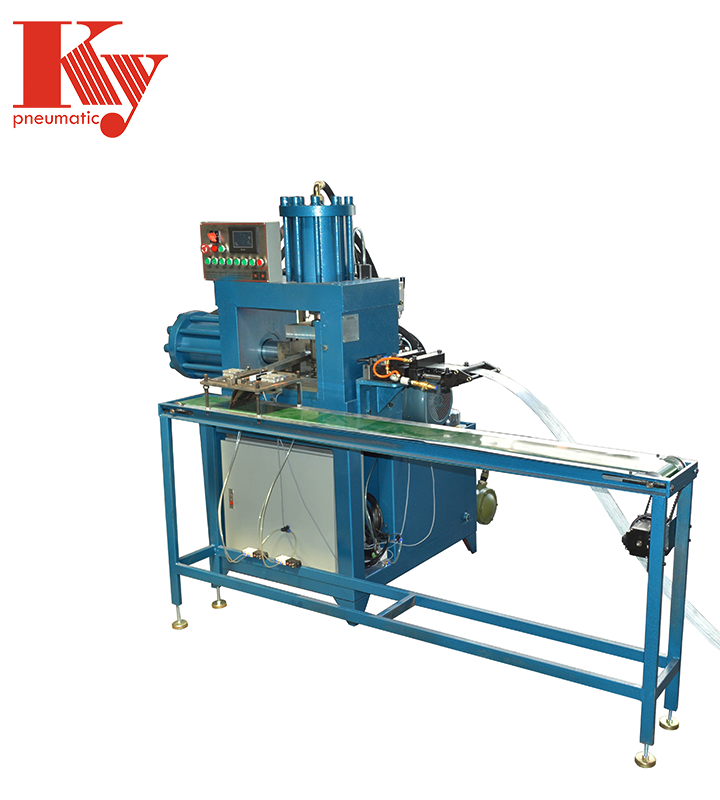

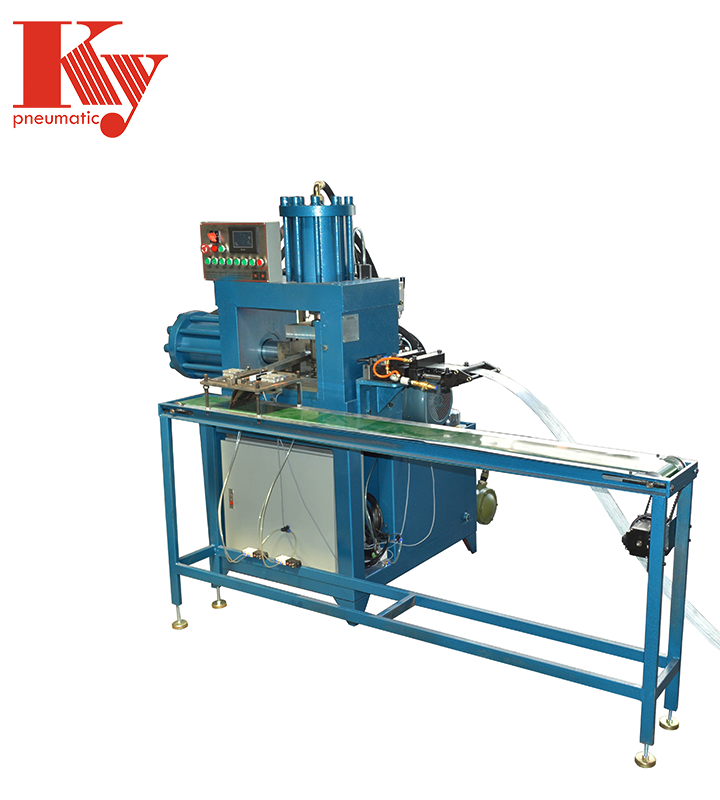

Established in 2018, Dongguan Shilong Ky Nailing Equipment Factory is a reputable manufacturer specializing in a variety of pneumatic staple and nail making machinery. Boasting robust technical expertise and production capabilities, we take pride in delivering high-quality solutions.

Our extensive product range encompasses staples and brad nail making machines, wire drawing machines, wire flattening machines, wire band machines, single wire staple making machines (Hog rings, C ring, etc.), mattress clip staple making machines, and 4K(90) high carbon steel staple making machines. Furthermore, our adept engineers and technical staff excel in customizing machines based on customers' specific requirements.

With years of dedication to this industry, we've established a closed-loop complete industry chain. This enables us to offer competitive prices and ensure the excellence of our machines. Our products have gained popularity among users in the Middle East, Asia, Africa, and Latin America.

Feel free to reach out to us for further information. Your inquiries are warmly welcomed.

With a focus on pneumatic staple and nail making machinery, we offer a diverse range of products, including staples and brad nail making machines, wire drawing machines, and more. Our extensive selection caters to various industrial needs, ensuring versatility and comprehensive solutions.

Our team of engineers and skilled technical staff excels in designing and developing machinery tailored to customers' specific requirements. This personalized approach ensures that our products meet the unique demands of clients, reflecting our commitment to innovation and flexibility.

Through years of dedication, we've established a closed-loop complete industry chain. This integrated approach allows us to provide customers with a competitive edge in terms of both pricing and machine quality. From production to delivery, we maintain a seamless process for customer satisfaction.

Trusted across continents, our products have gained popularity in regions like the Middle East, Asia, Africa, and Latin America. Our commitment to excellence, competitive pricing, and high-quality machines has earned us the trust of a diverse customer base, making us a reliable choice in the international market.

The machine features a magazine holding brad nails. Aligning it with the material, the user activates the trigger, driving the brad nail into the surface, ensuring a secure and discreet fastening.

The brad nail machine is widely used in carpentry, cabinetmaking, trim work, and other precision woodworking tasks due to its ability to work with small, lightweight brad nails.

The brad nail machine is designed to quickly and precisely drive slender brad nails into materials, commonly used in woodworking for fastening without causing excessive damage.

The brad nail machine can efficiently fasten materials such as wood, plastic, and other soft materials, offering versatility in various woodworking applications.

Copyright © © Copyright 2024 Dongguan Shilong Ky Nailing Equipment Factory all rights reserved