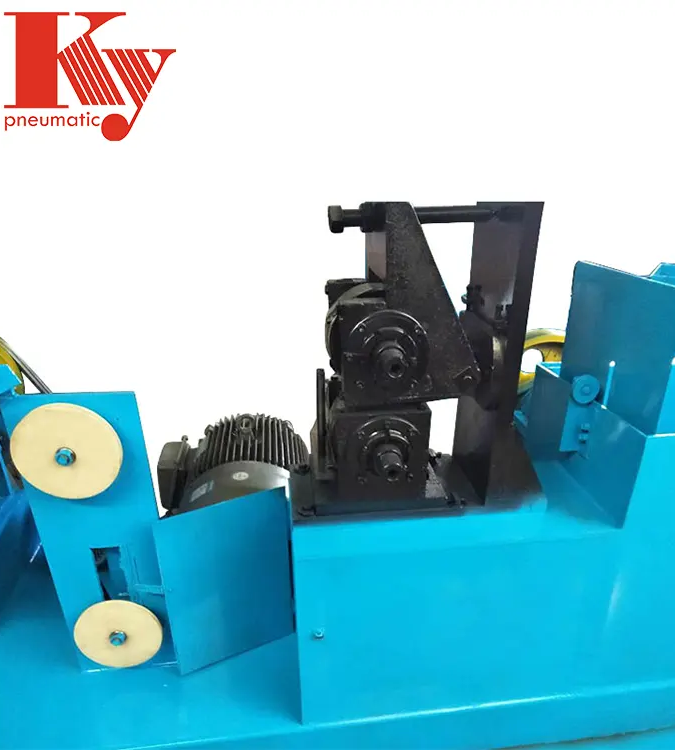

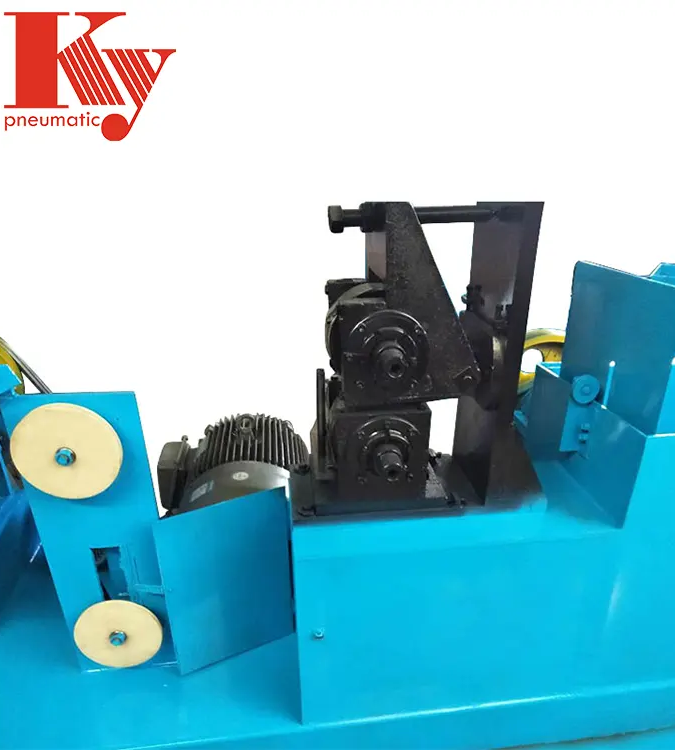

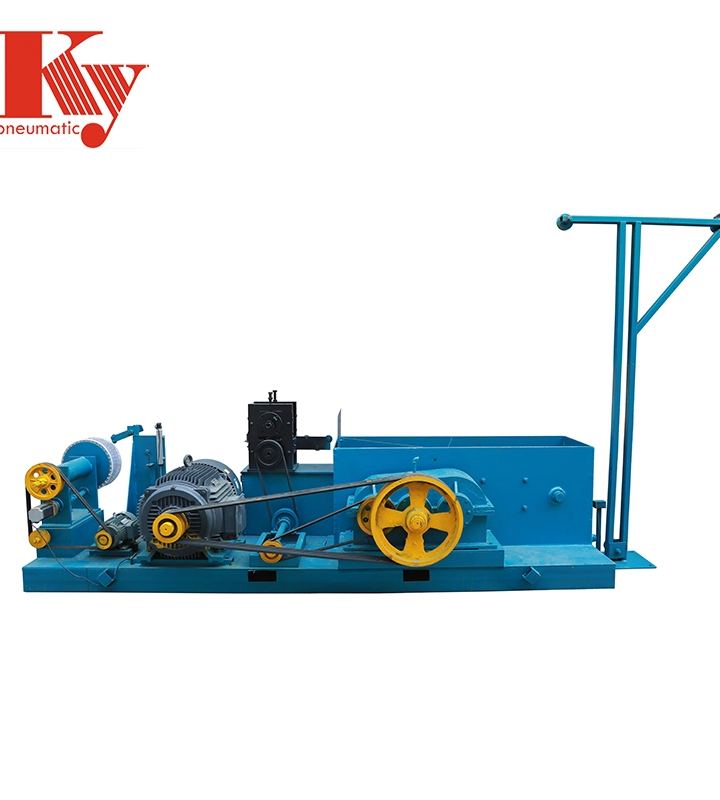

The mechanics of a wire drawing machine unfold as a symphony of precision and intricacy. At its core, this machine operates by subjecting a wire to a series of dies, typically crafted from robust materials like tungsten carbide. As the wire passes through these dies, its diameter undergoes a gradual reduction. The repetition of this process ensures not only precision but also uniformity, producing wires with consistent diameters that adhere to stringent industry standards. Understanding the operational nuances of the wire drawing machine unveils the mechanical ballet that shapes the wires essential to diverse applications.

The uses of wire drawing machines go beyond what a single industry can conceive. Such machines come out as versatile workhorses since they are used in the production of telecom cables, complex electrical wiring systems, and robust metallic cables for construction projects. Their changeability indicates their highly engineered nature, which allows producers to make wires with exact diameters that suit each purpose separately. This trait shows its technical might as well as it highlights it being an integral part of bettering end-products’ effectiveness and efficiency in different fields.

Unfolding the working principles of wire drawing machine reveals a mechanical masterpiece that generates a symphony of precision and intricacy. The basic operation involves pulling a wire rod through a set of carefully made dies, each made out of tough materials such as tungsten carbide. These dies that act like skilled craftsmen gradually reduce the diameter of the wire with skill, thereby effecting controlled and smooth transformation. This intricate procedure is characterized by repetition which guarantees precision and the ability to achieve exact desired wire diameter. Wire drawing machine makes its mark here, in this level of accuracy, where it meets or even surpasses stringent quality and uniformity requirements maintained for several industries.

The choice of wire drawing machine is a strategic one that requires careful consideration of various factors. Manufacturers navigate through difficult landscapes, taking into account such parameters as specification of diameter, production volume and rudimental automation. This is a strategic decision making process that will ensure the selected equipment is suitable for particular production needs thereby enhancing the efficiency and utilization of resources. These factors are what make a difference between these machines being seen as strategic assets in modern manufacturing or simply pieces of steel as they are supposed to be accurate and practical in most cases since manufacturing is so dynamic.

A wire drawing machine, which is a strong point of the industrial machinery world, has an essential part in making wires. This specialized tool testifies the engineering wonders that it takes to make thin wires – a vital task in the manufacture of different kinds of wires. Its multitude functionalities makes it a pillar in many industries that serves as an interface between technological creativity and manufacturing aptitude. In fine dance of making wires, the wire drawing machine appears as the principal actor changing raw materials into fundamental components that build many applications.

Established in 2018, Dongguan Shilong Ky Nailing Equipment Factory is a reputable manufacturer specializing in a variety of pneumatic staple and nail making machinery. Boasting robust technical expertise and production capabilities, we take pride in delivering high-quality solutions.

Our extensive product range encompasses staples and brad nail making machines, wire drawing machines, wire flattening machines, wire band machines, single wire staple making machines (Hog rings, C ring, etc.), mattress clip staple making machines, and 4K(90) high carbon steel staple making machines. Furthermore, our adept engineers and technical staff excel in customizing machines based on customers' specific requirements.

With years of dedication to this industry, we've established a closed-loop complete industry chain. This enables us to offer competitive prices and ensure the excellence of our machines. Our products have gained popularity among users in the Middle East, Asia, Africa, and Latin America.

Feel free to reach out to us for further information. Your inquiries are warmly welcomed.

With a focus on pneumatic staple and nail making machinery, we offer a diverse range of products, including staples and brad nail making machines, wire drawing machines, and more. Our extensive selection caters to various industrial needs, ensuring versatility and comprehensive solutions.

Our team of engineers and skilled technical staff excels in designing and developing machinery tailored to customers' specific requirements. This personalized approach ensures that our products meet the unique demands of clients, reflecting our commitment to innovation and flexibility.

Through years of dedication, we've established a closed-loop complete industry chain. This integrated approach allows us to provide customers with a competitive edge in terms of both pricing and machine quality. From production to delivery, we maintain a seamless process for customer satisfaction.

Trusted across continents, our products have gained popularity in regions like the Middle East, Asia, Africa, and Latin America. Our commitment to excellence, competitive pricing, and high-quality machines has earned us the trust of a diverse customer base, making us a reliable choice in the international market.

Wire drawing machines enhance efficiency by gradually reducing wire diameter through multiple dies, producing high-quality wire with desired specifications.

Industries such as electrical, telecommunications, and construction rely on wire drawing machines for manufacturing wires used in various applications.

Parameters like wire diameter requirements, production volume, and automation features play a crucial role in selecting the right wire drawing machine.

The wire drawing machine ensures the production of wires with precise diameters and smooth surfaces, contributing to the quality and functionality of end-products.

Copyright © 2025 by Dongguan Shilong Ky Nailing Equipment Factory