As technology strides forward, so does the brad nail machine. Positioned at the vanguard of innovation, manufacturers perpetually refine and enhance its features, integrating the latest advancements in materials and design. This unwavering commitment to progress ensures that the brad nail machine remains at the forefront of woodworking technology, facilitating efficiency, precision, and creativity in every project it undertakes. The brad nail machine stands not just as a tool but as a symbol of the ever-evolving landscape of woodworking excellence, embodying the convergence of tradition and innovation in the pursuit of perfection.

As technology continues to evolve, so is our dedication to wood work advances. As a section at the forefront of change, this part will outline how we continuously perfect and improves on characteristics of brad nail machines. The point is to integrate the most recent developments in materials and designs thereby making sure that our machine stays ahead in woodworking technology. Explore how our brad nail machine adds up in creating efficiency, accuracy and innovation into every wood working project with their commitment to quality as well as future forwardness within the industry. It’s not just about giving you a tool for today; it’s about laying foundations for tomorrow’s tools of woodworking. Our machine stands out as an evidence of how far we can go in pushing innovative boundaries hence making it an indisputable asset in an ever changing world of wooden excellence.

Our brad nail machine is a hallmark of precision, which is redefined in depth within the realm of woodworking accuracy. This part of the paper deconstructs fine points on how our tool works with precision. From the brilliantly designed magazine for one strip of brad nails to their seamless insertion into different surfaces, our devotion to precision is manifested at every step of the process. It entails a plunge into understanding how our brad nail machine simplifies complex tasks to linear steps and excels at meeting requirements set by exacting woodworking professionals whose demand is unrivaled accuracy. In other words, from our viewpoint, precision isn’t just seen as an attribute but rather it’s a philosophy that runs through each element in the design of this tool.

In order to address the diverse needs of our customers, we have come up with ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) customization options. This section will provide a step-by-step guide on how clients can modify the brad nail machine to fit their specific needs including size adjustments, changes in features or even branding. The idea behind the provision of a range of customization options is so that clients have an opportunity to determine how they want their machines to be built for them. Indeed, by making sure that it matches every craftsman’s/practitioner’s specific demand, our machinery proves itself flexible and therefore all-rounded. It is not only supplying a tool but also offering tailored solutions that best suit individual client vision and aspirations.

The crucial attribute of durability, which is a given in the unforgiving world of woodworking machinery, becomes the main focus as our brad nailer stands above the traditional expectations. This section will go behind the scenes to explain how these devices are built. It will describe the materials used and how they are tested for quality. The argument here is about how it is robust enough to withstand heavy usage, while at the same time being very reliable making it one of its kinds in wood working. In time though, craftspeople understand that our brad gun is not just a tool; it represents forever against all odds and any other form of challenges. This proves beyond any reasonable doubt that we take sustainability and performance seriously in every project that we undertake.

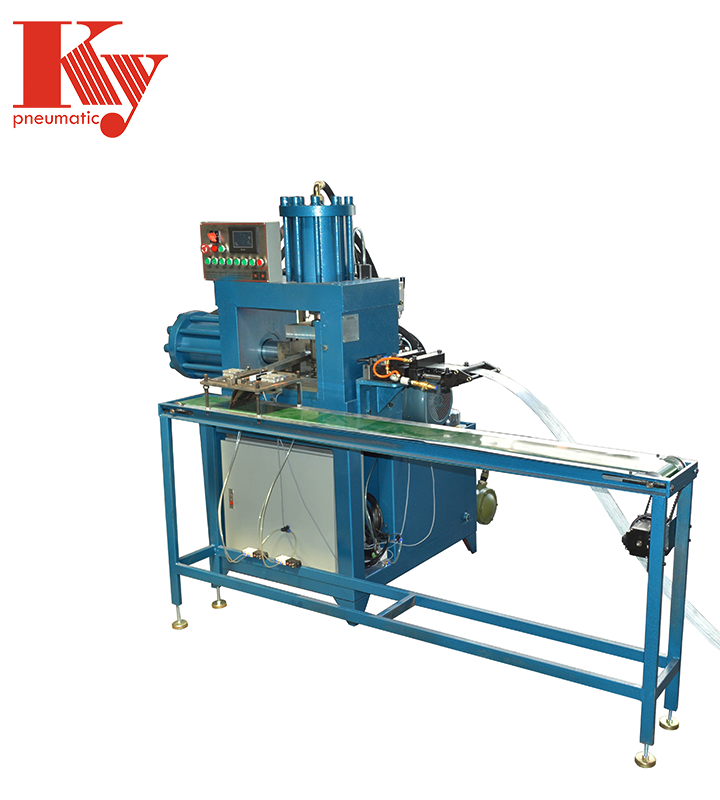

Established in 2018, Dongguan Shilong Ky Nailing Equipment Factory is a reputable manufacturer specializing in a variety of pneumatic staple and nail making machinery. Boasting robust technical expertise and production capabilities, we take pride in delivering high-quality solutions.

Our extensive product range encompasses staples and brad nail making machines, wire drawing machines, wire flattening machines, wire band machines, single wire staple making machines (Hog rings, C ring, etc.), mattress clip staple making machines, and 4K(90) high carbon steel staple making machines. Furthermore, our adept engineers and technical staff excel in customizing machines based on customers' specific requirements.

With years of dedication to this industry, we've established a closed-loop complete industry chain. This enables us to offer competitive prices and ensure the excellence of our machines. Our products have gained popularity among users in the Middle East, Asia, Africa, and Latin America.

Feel free to reach out to us for further information. Your inquiries are warmly welcomed.

With a focus on pneumatic staple and nail making machinery, we offer a diverse range of products, including staples and brad nail making machines, wire drawing machines, and more. Our extensive selection caters to various industrial needs, ensuring versatility and comprehensive solutions.

Our team of engineers and skilled technical staff excels in designing and developing machinery tailored to customers' specific requirements. This personalized approach ensures that our products meet the unique demands of clients, reflecting our commitment to innovation and flexibility.

Through years of dedication, we've established a closed-loop complete industry chain. This integrated approach allows us to provide customers with a competitive edge in terms of both pricing and machine quality. From production to delivery, we maintain a seamless process for customer satisfaction.

Trusted across continents, our products have gained popularity in regions like the Middle East, Asia, Africa, and Latin America. Our commitment to excellence, competitive pricing, and high-quality machines has earned us the trust of a diverse customer base, making us a reliable choice in the international market.

The machine features a magazine holding brad nails. Aligning it with the material, the user activates the trigger, driving the brad nail into the surface, ensuring a secure and discreet fastening.

The brad nail machine is widely used in carpentry, cabinetmaking, trim work, and other precision woodworking tasks due to its ability to work with small, lightweight brad nails.

The brad nail machine is designed to quickly and precisely drive slender brad nails into materials, commonly used in woodworking for fastening without causing excessive damage.

The brad nail machine can efficiently fasten materials such as wood, plastic, and other soft materials, offering versatility in various woodworking applications.

Copyright © © Copyright 2024 Dongguan Shilong Ky Nailing Equipment Factory all rights reserved