At the core of the brad nail machine's prowess lies its unparalleled functionality. This specialized device boasts a meticulously crafted magazine capable of holding a strip of brad nails, poised to be seamlessly deployed into surfaces encompassing wood, plastic, and other soft materials. Engineered for ergonomic excellence, the design ensures an intuitive operation – users can align the machine with precision and, with a gentle trigger pull, achieve flawless and secure attachments. This unparalleled precision renders the brad nail machine an ideal choice for intricate woodworking projects demanding the utmost accuracy, transforming complex tasks into streamlined operations.

Our brad nail machine has been designed with user comfort in mind, which is even more important than performance. The next part of this chapter dwells on how the ergonomically fashioned handle ensures a reliable and comfortable grip that makes it possible to use the tool for a long time without making muscles strain. Intuitively developed controls and an effective nail deliverance unit are analyzed in order to reveal their part in making workflow smoother and thus improving overall user satisfaction. This concern with the comforts of users, therefore, sets us apart from other firms who only focus on quality as opposed to also taking care of the health status of carpenters and furniture makers. Thus, our machine transcends being just a tool but becomes more like a companion that accompanies you throughout your journey as a carpenter, providing comfort every step of the way.

In order to address the diverse needs of our customers, we have come up with ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) customization options. This section will provide a step-by-step guide on how clients can modify the brad nail machine to fit their specific needs including size adjustments, changes in features or even branding. The idea behind the provision of a range of customization options is so that clients have an opportunity to determine how they want their machines to be built for them. Indeed, by making sure that it matches every craftsman’s/practitioner’s specific demand, our machinery proves itself flexible and therefore all-rounded. It is not only supplying a tool but also offering tailored solutions that best suit individual client vision and aspirations.

The crucial attribute of durability, which is a given in the unforgiving world of woodworking machinery, becomes the main focus as our brad nailer stands above the traditional expectations. This section will go behind the scenes to explain how these devices are built. It will describe the materials used and how they are tested for quality. The argument here is about how it is robust enough to withstand heavy usage, while at the same time being very reliable making it one of its kinds in wood working. In time though, craftspeople understand that our brad gun is not just a tool; it represents forever against all odds and any other form of challenges. This proves beyond any reasonable doubt that we take sustainability and performance seriously in every project that we undertake.

A game-changer in the woodworking industry, our brad nail machine is a sign of advanced engineering. At Brad Nailers USA, we are proud to present our brad nail machine which has been carefully made to enable thin brads to be driven through into a variety of material with such exactitude never seen before. This is the beginning of an account on how far our machine has gone in bringing about revolution within the woodwork enterprise by improving accuracy and speed. Esteemed woodworkers and craftsmen globally have taken up this innovation as a foundation stone for their quest for perfection, hailing it as the dawn of a new era in woodworking.

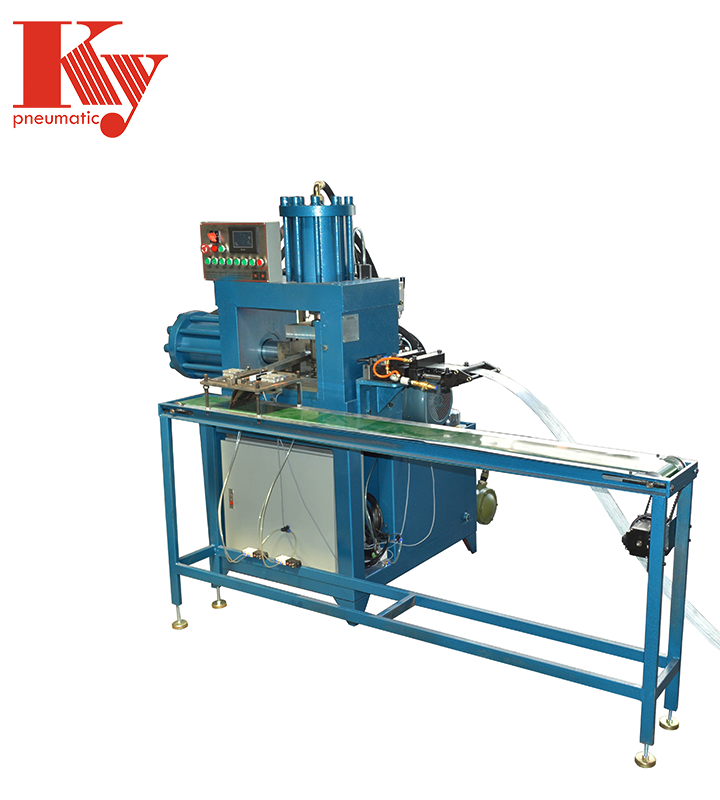

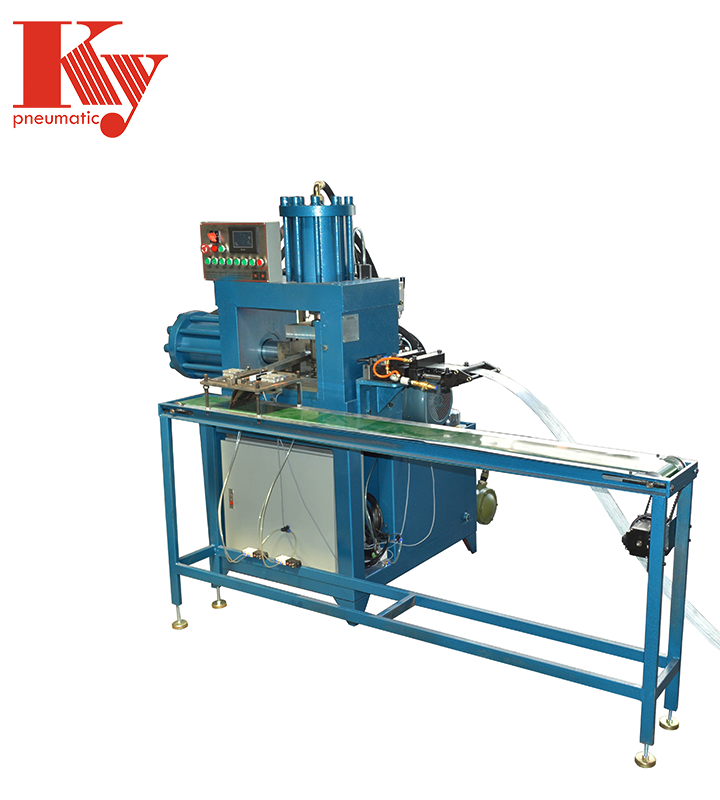

Established in 2018, Dongguan Shilong Ky Nailing Equipment Factory is a reputable manufacturer specializing in a variety of pneumatic staple and nail making machinery. Boasting robust technical expertise and production capabilities, we take pride in delivering high-quality solutions.

Our extensive product range encompasses staples and brad nail making machines, wire drawing machines, wire flattening machines, wire band machines, single wire staple making machines (Hog rings, C ring, etc.), mattress clip staple making machines, and 4K(90) high carbon steel staple making machines. Furthermore, our adept engineers and technical staff excel in customizing machines based on customers' specific requirements.

With years of dedication to this industry, we've established a closed-loop complete industry chain. This enables us to offer competitive prices and ensure the excellence of our machines. Our products have gained popularity among users in the Middle East, Asia, Africa, and Latin America.

Feel free to reach out to us for further information. Your inquiries are warmly welcomed.

With a focus on pneumatic staple and nail making machinery, we offer a diverse range of products, including staples and brad nail making machines, wire drawing machines, and more. Our extensive selection caters to various industrial needs, ensuring versatility and comprehensive solutions.

Our team of engineers and skilled technical staff excels in designing and developing machinery tailored to customers' specific requirements. This personalized approach ensures that our products meet the unique demands of clients, reflecting our commitment to innovation and flexibility.

Through years of dedication, we've established a closed-loop complete industry chain. This integrated approach allows us to provide customers with a competitive edge in terms of both pricing and machine quality. From production to delivery, we maintain a seamless process for customer satisfaction.

Trusted across continents, our products have gained popularity in regions like the Middle East, Asia, Africa, and Latin America. Our commitment to excellence, competitive pricing, and high-quality machines has earned us the trust of a diverse customer base, making us a reliable choice in the international market.

The machine features a magazine holding brad nails. Aligning it with the material, the user activates the trigger, driving the brad nail into the surface, ensuring a secure and discreet fastening.

The brad nail machine is widely used in carpentry, cabinetmaking, trim work, and other precision woodworking tasks due to its ability to work with small, lightweight brad nails.

The brad nail machine is designed to quickly and precisely drive slender brad nails into materials, commonly used in woodworking for fastening without causing excessive damage.

The brad nail machine can efficiently fasten materials such as wood, plastic, and other soft materials, offering versatility in various woodworking applications.

Copyright © © Copyright 2024 Dongguan Shilong Ky Nailing Equipment Factory all rights reserved